Cellulose diacetate

This article needs additional citations for verification. (June 2012) |

| |

| Identifiers | |

|---|---|

| |

| ChemSpider |

|

CompTox Dashboard (EPA)

|

|

| Properties | |

| variable | |

| Molar mass | variable |

Except where otherwise noted, data are given for materials in their standard state (at 25 °C [77 °F], 100 kPa). | |

| Infobox references | |

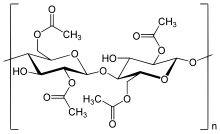

Cellulose diacetate, sometimes simply called diacetate, is a synthetic polymer made by treating cellulose with acetic acid. It consists of two acetyl functional groups on each unit of of the cellulose molecule. It was first developed in the United States.

It is distinguished from cellulose acetate and cellulose triacetate.

It is fragile since it is based on cellulose. When cellulose diacetate deteriorates, it shrinks and releases acetic acid, causing a "vinegar syndrome".

Cellulose diacetate has been used to make fabrics, membranes, filaments, and many consumer products. From 1922 to 1957 it was used to make film stock, mainly in smaller formats such as 8 mm, 16 mm, 35 mm, and 70 mm. It has also been used in seed coating applications.[1]

In photography, a film substrate made from cellulose diacetate is called safety film.

Cellulose diacetate is biodegradable and hydrophilic.

See also[]

References[]

- ^ Friuli, M., Nitti, P., Cafuero, L. et al. Cellulose Acetate and Cardanol Based Seed Coating for Intraspecific Weeding Coupled with Natural Herbicide Spraying. J Polym Environ (2020). https://doi.org/10.1007/s10924-020-01821-9

- Cellulose

- Science of photography

- Polymer stubs