Pratt & Whitney JT8D

| JT8D | |

|---|---|

| |

| The JT8D is a low-bypass turbofan often used on early narrowbody jetliners | |

| Type | Turbofan |

| National origin | United States |

| Manufacturer | Pratt & Whitney |

| First run | 1960 |

| Major applications | Boeing 727 Boeing 737-100/-200 McDonnell Douglas DC-9 McDonnell Douglas MD-80 |

| Number built | 14,750 [1] |

| Developed from | Pratt & Whitney J52 |

| Developed into | Volvo RM8 |

The Pratt & Whitney JT8D is a low-bypass (0.96 to 1) turbofan engine introduced by Pratt & Whitney in February 1963 with the inaugural flight of the Boeing 727. It was a modification of the Pratt & Whitney J52 turbojet engine which powered the US Navy A-6 Intruder attack aircraft. Eight models comprise the JT8D standard engine family, covering the thrust range from 12,250 to 17,400 pounds-force (62 to 77 kN) and power 727, 737-100/200, and DC-9 aircraft. The Volvo RM8 is an afterburning version that was license-built in Sweden for the Saab 37 Viggen fighter. Pratt & Whitney also sells static versions for powerplant and ship propulsion as the FT8.

Design[]

This section needs additional citations for verification. (October 2008) |

The JT8D is an axial-flow front turbofan engine incorporating design. There are two coaxially-mounted independent rotating assemblies: one rotating assembly for the low pressure compressor (LPC) which consists of the first six stages (i.e. six pairs of rotating and stator blades, including the first two stages which are for the bypass turbofan), driven by the second (downstream) turbine (which consists of three stages); and a second rotating assembly for the high-pressure compressor (HPC) section, which has seven stages. The high-pressure compressor is driven by the first (upstream) turbine, which has a single stage.

The front-mounted bypass fan has two stages. The annular discharge duct for the bypass fan runs along the full length of the engine, so that both the fan air and exhaust gases can exit through the same nozzle. This arrangement allows some noise attenuation, in that the still-hot fast-moving turbine exhaust is shrouded in much-cooler and slower-moving air (from the bypass fan) before interacting with ambient air. Thus the JT8D noise levels were significantly reduced from previous non-turbofan engines, although the low bypass ratio meant that, compared to subsequently developed turbofans, high noise levels were still produced.

Within the fan inlet case, there are anti-icing air bosses and probes to sense the inlet pressure and temperature. Similar units exist throughout the engine to check temperatures and pressures.

At the 13th (i.e. the final) compressor stage, air is bled out and used for anti-icing. The amount is controlled by the Pressure Ratio Bleed Control sense signal (PRBC). The diffuser case at the aft end of the compressor houses the 13th stage. Its increasing cross-sectional area allows the compressed air to slow down before entering one of the engine's nine burner cans. Again, there are two bosses to extract 13th stage air for anti-icing, de-icing of fuel, and airframe (cabin pressurization) use. Not all the compressed air enters the burner cans at the fuel-ignition point; some bypasses the can completely and cools the first turbine stage, and some is gradually introduced into the burner can's perimeter in such a way that the burning fuel is held near the can's centerline.

There are nine combustion chambers positioned in a can-annular arrangement. Each chamber has three air inlet hole sizes: the smallest is for cooling, the medium is for burning and the large for forming an air blanket.

- Details

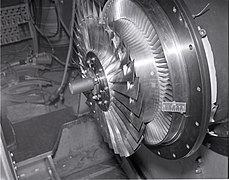

Canular combustor

20 in (510 mm) diameter rotor and bypass stator

Compressor fan

Fan blade

Update programs[]

In response to environmental concerns that began in the 1970s, the company began developing a new version of the engine, the JT8D-200 series.[2] Designed to be quieter, cleaner, more efficient, yet more powerful than earlier models, the -200 Series power-plant was re-engineered with a significantly higher bypass ratio (1.74 to 1) covering the 18,500 to 21,700 pound-force (82 to 97 kN) thrust range and powering the McDonnell Douglas MD-80 series. This increase was achieved by increasing bypass fan diameter from 39.9 inches (101 cm) to 49.2 inches (125 cm) and reducing fan pressure ratio (from 2.21 to 1.92).[citation needed] Overall engine pressure ratio was also increased from 15.4 to 21.0.[3] Since entering service in 1980, more than 2,900 of the -200 series engines have been produced.

The JT8D-217 and -219 engine(s) were tested in 2001 and were deemed suitable replacements for the old TF33 engines on military and commercial aircraft as part of the Super 27 re-engining program. The updated engines offer reduced (Stage-3) noise compliance standards without the need for hush kits, enhanced short field performance, steeper and faster climb rates with roughly a 10% reduction in fuel burn for extended range.

Pratt & Whitney, in a joint venture with Seven Q Seven (SQS) and Omega Air, has developed the JT8D-219 as a re-engine powerplant for Boeing 707-based aircraft.[4] Northrop Grumman used the -219 to re-engine one of the United States Air Force's fleet of 19 Joint Surveillance Target Attack Radar System (E-8 Joint STARS) aircraft, which would allow the JSTARS more time on station due to the engine's 17% [5] greater fuel efficiency. NATO plans to re-engine their fleet of E-3 Sentry AWACS aircraft. The -219 is publicized as being half the cost of the competing 707 re-engine powerplant, the CFM International CFM56, for reasons of geometrical and balance similarity to the engine it is replacing and the associated relative up-front wing modification costs of the two choices.[4][5]

The proposed Aerion SBJ supersonic business jet, previously under development, was to use a pair of JT8D-219 engines for sustained supersonic flight.

Variants[]

| Series | Initial J52 derived variants[6] | Updated -200 series[7] | |||||

|---|---|---|---|---|---|---|---|

| Model | -1(A/B)/7(A/B) /9(A)/11 |

-5 | -15(A) | -17(A/R/AR) | -209 | -217(A/C) | -219 |

| Certification | Feb 1, 1963 | Apr 7, 1971 | Feb 1, 1974 | Jun 22, 1979 | Oct 31, 1980 | Feb 22, 1985 | |

| Compressor | axial 13-stage | axial 14-stage | |||||

| Combustors, turbine | 9 can-annular, 4-stage | ||||||

| Maximum Thrust | 14,000–15,000 lbf 62–67 kN |

12,250 lbf 54.5 kN |

15,550 lbf 69.2 kN |

16,000–16,400 lbf 71–73 kN |

18,900 lbf 84 kN |

20,000 lbf 89 kN |

21,000 lbf 93 kN |

| Length | 123.56 in (3,138 mm) | 154.20 in (3,917 mm) | |||||

| Width | 40.0 in (1,020 mm) | 49.2 in (1,250 mm) | |||||

| Dry Weight | 3,205–3,402 lb 1,454–1,543 kg |

3,205 lb 1,454 kg |

3,414–3,474 lb 1,549–1,576 kg |

3,430–3,500 lb 1,560–1,590 kg |

4,588 lb 2,081 kg |

4,623–4,684 lb 2,097–2,125 kg |

4,684 lb 2,125 kg |

| LP rpm | 8,600 | 8,500 | 8,800 | 8,800-8,900 | 7,850 | 7,770-8,080 | 8,120 |

| HP rpm | 12,250 | 12,100 | 12,250 | 12,250-12,280 | 12,150 | 12,285-12,350 | 12,350 |

Production[]

More than 14,000 JT8D engines have been produced, totaling more than one-half billion hours of service with more than 350 operators making it the most popular of all low-bypass turbofan engines ever produced.[8][9] Regular production ended in 1985, but some replacement engines were produced for military aircraft in 2011.[10] Mainline airline use of the JT8D continued until 2020 when Delta Airlines retired their MD-88 fleet early due to the COVID-19 pandemic.[11]

Applications[]

- Aerion SBJ – proposed, not built

- Boeing 707RE

- Boeing 727 (Re-Engined Super 27s have JT8D-200s)

- Boeing 737-100 & -200

- Dassault Mercure

- Kawasaki C-1

- McDonnell Douglas DC-9

- McDonnell Douglas MD-80 series (JT8D-200s only)

- McDonnell Douglas YC-15

- Northrop Grumman E-8C Joint STARS – single testbed only

- Sud Aviation Caravelle 10B, 10R, 11R, and 12

- Pratt & Whitney FT8 MobilePac and SwiftPac mobile generators[12]

- Installations

Accidents[]

- 18 January 1969

- United Airlines Flight 266 – Ten minutes after takeoff, the cockpit received a warning from Engine 1 of an engine fire and cut off power to that engine. A minute later, Flight UA266 suffered a total loss of electrical power, which disabled the aircraft's flight instruments. At 13 minutes after take-off, the plane crashed into the Pacific Ocean, just 12 miles off the coast, killing all 38 people aboard the aircraft, which consisted of 32 passengers and six crew members.

- 4 April 1977

- Southern Airways Flight 242 – both engines on the DC-9 failed when the pilots flew into a severe thunderstorm after misreading their onboard radar. The flight encountered severe rain and hail. The NTSB concluded that the "loss of thrust was caused by the ingestion of massive amounts of water and hail which in combination with thrust lever movement induced severe stalling in and major damage to the engine compressors." Some 63 people on board and nine on the ground died as a result of the accident.

- 22 August 1985

- British Airtours Flight 28M – an engine failed during take-off from Manchester Airport and a fire spread into the cabin, resulting in 55 fatalities aboard the Boeing 737-236 Advanced.

- 6 September 1985

- Midwest Express Flight 105 – NTSB concluded that an unconfined failure of the 9th - 10th stage compressor spacer occurred immediately after takeoff from Milwaukee Mitchell International Airport (then called Billy Mitchell Field). The plane was observed to have slowed significantly as a result of the engine loss and experienced an accelerated stall condition. The plane rolled to the right 90 degrees and crashed just south of the runway, resulting in 31 fatalities (all passengers and crew) aboard the McDonnell-Douglas DC-9 aircraft.[13]

- 3 May 1991

- Ryan Airlines – Unconfined failure of 9th stage compressor disc penetrated fuel lines and fuselage on the tarmac at Bradley International Airport causing fire and complete loss of aircraft. No fatalities reported.[14]

- 21 December 1991

- Scandinavian Airlines Flight 751 – The engines on an MD-81 ingested wing ice during takeoff causing engine damage that led to a total loss of thrust on both engines. The aircraft crashed in a forest clearing with no fatalities.

- 6 July 1996

- An engine explosion happened on an MD-88, Delta Air Lines Flight 1288, just prior to take-off at Pensacola, Florida, USA, with two fatalities.

- 15 April 2008

- A DC-9-51 operated by Hewa Bora Airways crashed and burned at Goma following an engine fire, with 40 fatalities.

- 10 July 2019

- A McDonnell Douglas MD-88 operated by Delta landed safely after an engine failure.[15]

- 2 July 2021

- Transair Flight 810 – One engine on the Boeing 737-200 cargo aircraft failed en route from Honolulu to the neighboring Hawaiian island of Maui. The crew attempted to turn back to Honolulu's Daniel K. Inouye International Airport, but the plane's second engine overheated, forcing the two pilots on board to ditch the airplane about 4 miles (6.4 km) off the southern coast of Oahu. Both pilots were rescued by the United States Coast Guard.[16]

Specifications (JT8D-219)[]

Data from PW[17]

General characteristics

- Type: Dual-spool, low-bypass turbofan

- Length: 154 in (390 cm)

- Diameter: 49.2 in (125 cm) fan

- Dry weight: 4,741 lb (2,150 kg)

Components

- Compressor: Axial flow, 1-stage fan, 6-stage LP, 7-stage HP[verification needed]

- Combustors: Nine can-annular ("cannular") chambers[verification needed]

- Turbine: 1 stage HP, 3 stage LP[verification needed]

- Fuel type: 1

- Oil system: 2

Performance

- Maximum thrust: 21,000 lbf (93 kN)

- Overall pressure ratio: 19.4

- Air mass flow: 331 lb/s (150 kg/s)[verification needed]

- Fuel consumption: 19% reduction over JT3D

- Specific fuel consumption: 0.744 kg/daN/h (0.730 lb/lbf/h)[verification needed]

- Thrust-to-weight ratio: 4.43

See also[]

Related development

Comparable engines

Related lists

References[]

- ^ https://pw.utc.com/en/products-and-services/products/commercial-engines/jt8d JT8D ENGINE

- ^ Gunston, Bill (1999). The Development of Piston Aero Engines, 2nd Edition. Sparkford, Somerset, England, UK: Patrick Stephens, Haynes Publishing. p. 169. ISBN 0-7509-4478-1.

- ^ Pratt & Whitney website, accessed 14 October 2007

- ^ Jump up to: a b Flug Revue, May 12, 2002 Archived November 7, 2007, at the Wayback Machine

- ^ Jump up to: a b Re-engining the E-8 JSTARS, May 14, 2008

- ^ "Type Certificate E2EA data sheet" (PDF). Federal Aviation Administration. August 28, 2007.

- ^ "Type Certificate E9NE data sheet" (PDF). Federal Aviation Administration. December 13, 2010.

- ^ "Pratt & Whitney's JT8D Engine Turns Half a Century Old". MediaRoom. Pratt and Whitney. Retrieved 2021-07-07.

More than 14,750 JT8D engines have been built, accumulating more than half a billion hours of service. At one point, JT8D engine sales and service contributed about half of United Technologies' profits. Today, it continues to generate revenue through overhauls, spare parts sales and kits to make it quieter and cleaner burning.

- ^ "JT8D". Pratt and Whitney. Retrieved 2021-07-07.

The JT8D engine has proven itself to be a highly durable and reliable engine, having completed more than 673 million dependable flying hours since entering service. Once deemed the workhorse of the industry, more than 14,750 JT8D engines have flown. Today, there are 2,400 engines still in use.

- ^ Lee, Mara (2011-03-03). "JT8D Engine Revived At Pratt & Whitney". Hartford Courant. Retrieved 2021-07-07.

- ^ McMurtry, Ian (2020-06-03). "The JT8D Engine Roars into History Books as Delta Retires McDonnell Douglas Fleet". AirlineGeeks.com. Retrieved 2021-07-08.

- ^ Pratt & Whitney Celebrates Completion of 50th FT8 MobilePac Power Generator: Hartford Courant, July 18, 2011

- ^ https://www.ntsb.gov/investigations/AccidentReports/Reports/AAR8701.pdf | NTSB Aircraft Accident Report AAR8701

- ^ "ASN Aircraft accident Boeing 727-22QC N425EX Hartford-Bradley International Airport, CT (BDL)". Aviation Safety Network.

- ^ "A Delta flight was forced to make an emergency landing when one of the plane's engines failed". 10 July 2019.

- ^ Shapiro, Emily; Stone, Alex (July 2, 2021). "2 pilots alive after plane crashes few miles off coast of Hawaii". ABC News. Retrieved 2021-07-02.

- ^ "JT8D-219Turbofan Engine" (PDF). Pratt & Whitney. September 2010. Archived from the original (PDF) on 2017-05-10. Retrieved 2016-08-25.

External links[]

| Wikimedia Commons has media related to Pratt & Whitney JT8D. |

| This aircraft engine article is missing some (or all) of its specifications. If you have a source, you can help Wikipedia by . |

- Low-bypass turbofan engines

- Pratt & Whitney aircraft engines

- 1960s turbofan engines