Textile bleaching

The textile bleaching (or bleaching of textiles) is one of the steps in the textile manufacturing process. The objective of bleaching is to remove the natural color for the following steps such as dyeing or printing or to achieve full white.[1] All raw textile materials, when they are in natural form, are known as 'greige' material. They have their natural color, odor and impurities that are not suited to clothing materials. Not only the natural impurities will remain in the greige material, but also the add-ons that were made during its cultivation, growth and manufacture in the form of pesticides, fungicides, worm killers, sizes, lubricants, etc. The removal of these natural coloring matters and add-ons during the previous state of manufacturing is called scouring and bleaching.[2]: 193 [3][4][5]

History[]

Grassing is one of the oldest methods of bleaching textile goods. To bleach linen and cotton-based fabrics, the Grassing method has been used. Linen has long been bleached in Europe with Grassing method.[6] The linens were laid out on the grass for over seven days after boiling with the ''lyes of ashes and rinsing''.[7] Bleachfield was an open area to spread cloth, it was an field near watercourse used by a bleachery. Bleachfields were common in and around the mill towns during the British Industrial Revolution[8]

Discovery of Chlorine[]

After discovering Chlorine in the late 18th century, when chemical bleaching came into existence, the chemical bleaching rose above Grassing, as it was quicker and possible in indoors.[6][8][7]

Scouring[]

Scouring is the first process carried out with or without chemicals, at room temperature or at suitable higher temperatures with the addition of suitable wetting agents, alkali and so on. Scouring removes the impurities such as waxes, pectins and makes the textile material hydrophilichy or water absorbent.[9][10][11]: 78 Scouring is then followed by the bleaching process.[2]: 169 [2]: 193

Bleaching[]

Bleaching is the process of decolorizing the material after it has been scoured.[2]: 169 Bleaching textiles can be classified as oxidative bleaching and reductive bleaching which can be carried out with oxidizing and reductive bleaching agents.[12]: 161 Bleaching agents attack the chromophores and alter the color absorbing properties of the objects.[13]

Oxidative bleaching[]

Generally oxidative bleachings are carried out using sodium hypochlorite, sodium chlorite or sulfuric acid.

Vegetable fibres, animal fibers, and mineral fibres are the three major types of natural fibers. Natural fibers such as cotton, ramie, jute, wool, and regenerated fibers such as bamboo are all generally bleached with oxidative methods.[14]

Oxygen bleaching action[]

It is the conjugated double bonds of the substrate that makes the substrate capable of absorbing visible light. Hence, it looks yellower and need bleaching. When bleaching action carries out with oxygen, it removes the chromophoric sites and makes the cloths whiter. Oxygen is a degrading bleaching agent. Its bleaching action is based on ''destroying the phenolic groups and the carbon–carbon double bonds.''.[15] The major source of chemical bleaching is Hydrogen peroxide H

2O

2 that contains a single bond, (–O–O–). When this breaks down it gives rise to very reactive oxygen specie, which is the active agent of the bleach. Around sixty percent of the world Hydrogen peroxide is used in chemical bleaching of textiles and wood pulp.[16]

Reductive bleaching[]

Reductive bleaching is done with sodium hydrosulphite, a powerful reducing agent. Fibres like polyamides, polyacrylics and polyacetates can be bleached using reductive bleaching technology.[14]

Textile whitening[]

Bleaching of textiles may include an additional application of optical brighteners (OBAs). Optical brightening agents are chemical compounds that absorb light in the ultraviolet and violet region (usually 340-370 nm) of the electromagnetic spectrum, and re-emit light in the blue region (typically 420-470 nm) by fluorescence. After scouring and bleaching, optical brightening agents are applied to make the textile material appear a more brilliant white. These OBAs are available in different tints such as blue, violet and red.[17]

Whiteness[]

Whiteness in colorimetry is the degree to which a surface is white.[18] The term "whiteness" refers to the degree to which a surface resembles the properties of a perfect reflecting diffuser, i.e. an ideal reflecting surface that neither absorbs nor transmits light, but instead reflects it evenly in all directions.[19]

CIE Whiteness[]

CIE Whiteness is a formula that measures the degree of whiteness.[19] The CIE Whiteness Index is a measure or methodology developed by the Commission on illumination.[20]

Gallery[]

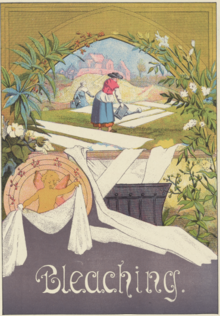

Grassing, laying out linens to bleach in sunlight

Linen Bleaching/ Grassing

Bleekveld in een dorp (Bleachfield in a village), circa 1650 (Jan Brueghel the Younger)

Market and washing place in Flanders

Bleaching vats for cloth in the piece.

High Pressure Blow-through Kier

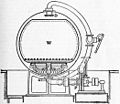

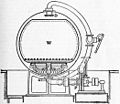

Bleaching—The Mather Kier, cross section

Bleaching—The Mather Kier, cross section

Bleaching—The Mather Kier, longitudinal section

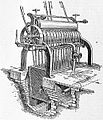

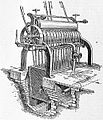

Bleaching—Mather & Platt’s Horizontal Drying Machine

Bleaching—Horizontal Drying Machine threaded with Cloth

See also[]

References[]

- ^ Hummel, J. J. (John James) (1898). The dyeing of textile fabrics. Harvard University. London [etc.] New York, Cassell and company, limited. p. 86.

- ^ a b c d Hall, A. J. (Archibald John) (1969). The standard handbook of textiles. Internet Archive. New York, Chemical Pub. Co.

- ^ Clark, M. (2011-10-25). Handbook of Textile and Industrial Dyeing: Principles, Processes and Types of Dyes. Elsevier. pp. 65, 66. ISBN 978-0-85709-397-4.

- ^ The Cotton Year Book and Diary. Marsden and Company, Limited. 1919. p. 470.

- ^ "Impurity - an overview | ScienceDirect Topics". www.sciencedirect.com. Retrieved 2021-07-31.

- ^ a b Nystrom, Paul Henry (1916). Textiles. D. Appleton. p. 266.

Grassing . — The oldest bleaching method is that of "grassing", still used to a certain extent in Europe for bleaching linens . The linen fabrics are laid on the grass or ground for weeks . The oxygen of the air and that given off by green plants

- ^ a b Sansone, Antonio (1888). Dyeing: Comprising the Dyeing and Bleaching of Wool, Silk, Cotton, Flax, Hemp, China Grass &c. A. Heywood & son. p. 109.

- ^ a b Aspin, C. (Christopher) (1981). The cotton industry. Internet Archive. Aylesbury : Shire Publications Ltd. p. 24. ISBN 978-0-85263-545-2.

- ^ Faculty Of Engineering. p. 18.

- ^ Horrocks, A. Richard; Anand, Subhash C. (2015-12-01). Handbook of Technical Textiles: Technical Textile Processes. Woodhead Publishing. p. 191. ISBN 978-1-78242-481-9.

- ^ Trotman, E. R. (Edward Russell) (1968). Textile scouring and bleaching. Internet Archive. London, Griffin. ISBN 978-0-85264-067-8.

- ^ Karmakar, S. R. (1999-11-02). Chemical Technology in the Pre-Treatment Processes of Textiles. Elsevier. ISBN 978-0-08-053947-8.

- ^ "Bleaching Agent - an overview | ScienceDirect Topics". www.sciencedirect.com. Retrieved 2021-08-01.

- ^ a b The Indian Textile Journal. Indian Textile Journal Limited. 2012. p. 113.

- ^ "Bleaching Agent - an overview | ScienceDirect Topics". www.sciencedirect.com. Retrieved 2021-07-27.

- ^ Hage, Ronald; Lienke, Achim (2006). "Applications of Transition-Metal Catalysts to Textile and Wood-Pulp Bleaching". Angewandte Chemie International Edition. 45 (2): 206–222. doi:10.1002/anie.200500525. ISSN 1521-3773. PMID 16342123.

- ^ Smulders, Eduard; Rybinski, Wolfgang von; Sung, Eric; Rähse, Wilfried; Steber, Josef; Wiebel, Frederike; Nordskog, Anette (2007), "Laundry Detergents", Ullmann's Encyclopedia of Industrial Chemistry, American Cancer Society, doi:10.1002/14356007.a08_315.pub2, ISBN 978-3-527-30673-2, retrieved 2021-08-01

- ^ Colorimetry : understanding the CIE system. János Schanda, International Commission on Illumination. [Vienna, Austria]: CIE/Commission internationale de l'eclairage. 2007. ISBN 978-0-470-17563-7. OCLC 181346337.

{{cite book}}: CS1 maint: others (link) - ^ a b Westland, Stephen (2014), "CIE Whiteness", in Luo, Ronnier (ed.), Encyclopedia of Color Science and Technology, Berlin, Heidelberg: Springer, pp. 1–5, doi:10.1007/978-3-642-27851-8_5-1, ISBN 978-3-642-27851-8, retrieved 2021-08-01

- ^ Amutha, K. (2016-04-05). A Practical Guide to Textile Testing. CRC Press. p. 105. ISBN 978-93-85059-62-9.

External links[]

| Wikisource has the text of the 1911 Encyclopædia Britannica article "Bleaching". |

- Textile Processing Guide at thesmarttime.com

- Textiles

- Industrial processes

- Textile techniques

- Industry stubs