Compressed air car

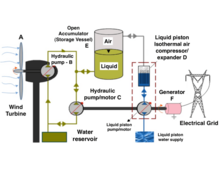

A compressed-air car is a compressed-air vehicle fuelled by pressure vessels filled with compressed air and propelled by the release and expansion of the air within a Pneumatic motor or motor adapted to compressed air. The car can be powered solely by air, or combined (as in a hybrid electric vehicle) with gasoline, diesel, ethanol, or an electric plant with regenerative braking. operate according to a thermodynamic process where air cools down when expanding and heats up when being compressed and those are thermal energy losses that drain the capacity factor of compressed air, however with the recent developments in isothermal compressed air energy storage plants, compressed air storage has reached 4 times the capacity factor of lithium-ion batteries with 2.7Mj/kg or 3.6Mj/m3 [3] and in 2020 there has been developments in ICAV car or isothermal compressed air vehicle published by Dr. Reza Alizade Evrin from Ontario Tech University[1][2] with a first prototype that uses low pressure air tanks and exhaust air recovery to power a paraffin heat exchanger system with a global energy efficiency of 74% (reaching 73%-90% efficiency of lithium-ion electric cars) with a driving range of 140 km. This efficiency and range can be increased by using storage tank as car chassis structure, high pressure tanks, new rotary engines, and a more efficient heat exchanger, this breakthrough together with the availability of recycled and bio-based thermoplastics for tanks and pneumatic components and renewable energy means this technology can be the basis of a free green transportation revolution with energy and decentralization with open source numerical control machines fabrication including additive manufacturing while multistage air compressors and coolers or hydraulic pumps can be attached directly to wind turbines, stirling engine with a parabolic or fresnel lens solar concentrator or river, tidal, wave hydropower turbine with no electric energy or electric grid needed nor energy conversion inefficiencies or additional energy storage, also instead of onboard heat recovery system there can be used a refillable molten salt (from fresnel lens or parabolic Concentrated solar power) reservoir in a heat exchanger system.

Tech[]

Engines for compressed air[]

There have been several dubious claims with undisclosed information however the "di pietro" engine has been partially tested with CAD and finite element analysis program and published in scientific papers by from Lodz University of Technology in 2017,[5] which is an eccentric shaft vane motor that uses low air pressure. Another recent engine that could be adapted to compressed air is LiquidPiston rotary engine.[4]

Compressed air tanks and collision safety[]

The tanks must be designed to safety standards appropriate for a pressure vessel, such as ISO 11439.[7]

The pressure vessels or air storage tanks that can be used in compressed air cars can be made of low pressure (9 atm) or high pressure (+240 atm), and can be made of composite materials like thermoplastic and fiber reinforced thermoplastics,[6][8] that means that the price can drop by using recycled or biobased thermoplastics using rotational molding and they are much lighter than batteries and 70% lighter compared to steel tanks, also they have more lifespan and don't need much maintenance.

To reduce car weight further the pressure vessels can be used as structural storage so the tank is the main part of the car chassis while using appropriate impact isolation, however fiber reinforced thermoplastic tanks only have ruptures in case of collision and don't explode. The advance in pressure vessels for cars have been developed for hydrogen cars with high compression pressure vessels, this is a quote from hyundai webpage which have created the Hyundai Nexus with 700 atm tanks and favourable crash tests.[9]

” Hydrogen tanks require ‘High Strength’ to prevent rupture and ‘High Stiffness’ for durability. Strength is defined as the level of resistance to an influence of an external force. Stiffness is the level of resistance maintaining its original shape. The carbon fiber materials used in making hydrogen fuel tanks is as light as a plastic but has six and four times the strength and stiffness of steel, respectively. “When a bullet penetrates a hydrogen tank, it does not explode. Instead, hydrogen leaks out through the bullet hole. In a standard collision test, not even a tiny amount of hydrogen was detected because none had leaked out.

Compressed air production, storage and energy efficiency and density[]

Compressed air has a low energy density, however near isothermal compressed air storage has almost 4 times lithium-ion batteries capacity with 2.7Mj/kg or 3.6Mj/m3.[3] Also Compressed air can be produced by attaching an air compressor or hydraulic pump to a wind turbine [10][11] or using river, tidal, wave hydropower turbine with only a conversion from mechanical to pneumatic energy eliminating electricity from the loop that gives higher efficiency overall, also there's the possibility of using thermal energy with a parabolic or fresnel lens solar concentrator to power a thermal stirling engine to move the compressor or pump, solar stirling is more efficient than solar steam and Photovoltaic.

Emissions[]

Compressed air cars nor only are emission free but also electric energy free since a wind turbine can be attached to an air compressor or hydraulic pump or a stirling engine to a parabolic or fresnel lens solar concentrator. In other words, the deployment of compressed air cars do not rely from petrol stations¡s compressed air or electric grid infrastructure.

Since the compressed air is filtered to protect the compressor machinery, the air discharged has less suspended dust in it, though there may be carry-over of lubricants used in the engine that can be mitigated by using oil free wind turbine air compressors with wind turbine powered intercoolers

Resource consumption[]

The recent developments of composite pressure vessels and pneumatic components means that compressed air cars can be part of the with or recycled components, also by cutting electric energy from the loop there's no need for electric grid and the metals used like cooper, iron in magnets, etc.

Advantages[]

Energy efficiency of the energy source, by using wind turbines to compressors or pumps there's a single conversion of mechanical to pneumatic or hydraulic energy,[11] and by powering the compressor with stirling engine with a parabolic or fresnel lens solar concentrator there's thermal energy to mechanical energy conversion, also by using a phase change material in the heat exchanger heated with concentrated solar power there's only solar thermal energy involved.

Energy efficiency of the vehicle compared to lithium-ion, as of 2020 the first isothermal prototype reaches 74%,[1][2] which is similar to the 73-90% of electric vehicles

Energy density compared to lithium-ion, Isothermal compressed air energy storage energy density can be at least 2.7Mj/kg or 3.6Mj/m3, 4 times [3] of lithium-ion batteries, which can be improved with high pressure vessels and heat exchanger systems.

Resources, compressed air technology can be adapted to renewable energy and with or recycled composites and so compared to electric carss they can be exempt from finite mineral resources or toxic processes used in battery and electric motor manufacturing and also from the electric grid use.[6]

, the low weight of composite pressure vessels relative to lithium-ion battery and also compared to steel tanks (70% lighter),[8] which that can be reduced by using the tanks as car chassis structure with appropriate impact isolation, also the low weight of wheel hub motor rotary engines.

in almost any place or with onboard equipment because only is necessary wind, solar power or river, tidal, wave hydropower to move an air compressor, hydraulic pump or stirling engine.

with the available pneumatic energy, so all car mechatronics systems can be powered by small air motors, and also the car can use , or pneumatic shock absorption bumpers,[12] also there can be provided air conditioning or climate control with the using the low temperature created during air expansion.

Energy recovery systems with and Regenerative braking producing to be stored in an additional pressure vessel.

Low noise of pistonless rotary engines while using compressed air, which can also being soundproofed because the low temperature in which it works, therefore air powered engines can be virtually silent[13]

Zero fire hazard, which makes it one of the few transportation systems that cannot produce spontaneous or after-collision fire or explosions like in the case of petrol, ethanol, hydrogen and also battery vehicles.

Compressed air engines reduce the cost of car production, because there is no need to build a cooling system, spark plugs, starter motor, or mufflers.

The rate of self-discharge is very low opposed to batteries that deplete their charge slowly over time. Therefore, the vehicle may be left unused for longer periods of time than electric cars.

Reduction or elimination of hazardous chemicals such as gasoline or battery acids/metals

Compressed air cars can be used in certain situation without any issues:

- potentially explosive work atmospheres

- the vicinity of strong magnetic electric fields

- Radio Quiet Zones

Disadvantages[]

Energy density of compressed air compared to liquid nitrogen or hydrogen.

Energy efficiency of compressed air engine compared to micro gas turbine with adequate soundproofing that can be used in hybrid gas turbine-electric motor vehicles with a mixture of compressed air, liquid nitrogen or hydrogen (previous have used a setup for speed rather than efficiency consisting in a large noise gas turbines connected to the transmission) since the gas turbine (which are used in thermal power plants due to its efficiency) outperforms pistonless rotary engines, however the production of compressed air is more energy efficient and so requires less wind power and infrastructure and also there's a loss of efficiency from gas turbine to generator and to electric motor.

While batteries can somewhat maintain their voltage throughout their discharge and chemical fuel tanks provide the same power densities from the first to the last litre, the pressure of compressed air tanks falls as air is drawn off, what can be mitigated by using an additional engine for lower pressure in roads with no slope.

Developers and manufacturers[]

Various companies are investing in the research, development and deployment of Compressed air cars. Overoptimistic reports of impending production date back to at least May 1999. For instance, the MDI Air Car made its public debut in South Africa in 2002,[14] and was predicted to be in production "within six months" in January 2004.[15] As of January 2009, the air car never went into production in South Africa. Most of the cars under development also rely on using similar technology to low-energy vehicles in order to increase the range and performance of their cars.[clarification needed]

MDI[]

MDI has proposed a range of vehicles made up of AIRPod, OneFlowAir, CityFlowAir, MiniFlowAir and MultiFlowAir.[16] One of the main innovations of this company is its implementation of its "active chamber", which is a compartment which heats the air (through the use of a fuel) in order to double the energy output.[17] This 'innovation' was first used in torpedoes in 1904.

Tata Motors[]

As of January 2009 Tata Motors of India had planned to launch a car with an MDI compressed air engine in 2011.[18][19] In December 2009 Tata's vice president of engineering systems confirmed that the limited range and low engine temperatures were causing problems.

Tata Motors announced in May 2012[20] that they have assessed the design passing phase 1, the "proof of the technical concept" towards full production for the Indian market. Tata has moved onto phase 2, "completing detailed development of the compressed air engine into specific vehicle and stationary applications".[21]

In February 2017 Dr. Tim Leverton, president and head at Advanced and Product Engineering at Tata revealed was at a point of "starting industrialisation" with the first vehicles to be available by 2020.[22] Other reports indicate Tata is also looking at reviving plans for a compressed air version of the Tata Nano,[23] which had previously been under consideration as part of their collaboration with MDI.[24]

Engineair Pty Ltd[]

Engineair is an Australian company which has produced prototypes of a variety of prototype small vehicles using an innovative rotary air engine designed by Angelo Di Pietro. The company is seeking commercial partners to utilise its engine.[25]

Peugeot/Citroën[]

Peugeot and Citroën announced that they intended to build a car that uses compressed air as an energy source. However, the car they are designing uses a hybrid system which also uses a gasoline engine (which is used for propelling the car over 70 km/h, or when the compressed air tank has been depleted).[26][27] In January 2015, there was "Disappointing news from France: PSA Peugeot Citroën has put an indefinite hold on the development of its promising-sounding Hybrid Air powertrain, apparently because the company has been unable to find a development partner willing to split the huge costs of engineering the system." Development costs are estimated to 500 million Euro for the system, which would apparently have need to be fitted to around 500,000 cars a year to make sense. [28] The head of the project left Peugeot in 2014.[29]

APUQ[]

APUQ (Association de Promotion des Usages de la Quasiturbine) has made the APUQ Air Car, a car powered by a Quasiturbine.[30]

See also[]

- Air engine

- Charging station

- Compressed air energy storage

- Compressed air battery

- Compressed air vehicles

- Engine swap

- Plug-in hybrid

- Pneumatics

References[]

- ^ Jump up to: a b c "Compressed air cars for urban transportation". advancedsciencenews. Retrieved 2020-09-07.

- ^ Jump up to: a b c "Experimental investigation of a compressed air vehicle prototype with phase change materials for heat recovery". onlinelibrary.wiley. Retrieved 2020-04-27.

- ^ Jump up to: a b c "Thermal analysis of near-isothermal compressed gas energy storage system". semantic scholar. Retrieved 2016-07-13.

- ^ Jump up to: a b "Development of a Small Rotary SI/CI Combustion Engine". researchgate.net. 2014-07-18. Retrieved 2014-10-13.

- ^ "Design type air engine Di Pietro". researchgate.net. 2017-07-18. Retrieved 2017-10-13.

- ^ Jump up to: a b c "Thermoplastic composite pressure vessels for FCVs". compositesworld.com. 2015-02-01. Retrieved 2015-02-01.

- ^ "Gas cylinders – High pressure cylinders for the on-board storage of natural gas as a fuel for automotive vehicles". Iso.org. 2006-07-18. Retrieved 2010-10-13.

- ^ Jump up to: a b "High pressure gas tanks in thermoplastic composites". plastics.gl. 2014-05-01. Retrieved 2014-05-01.

- ^ "OHydrogen Tank: Safety Proven (OA-ICAES) System". hyundaimotorgroup. Retrieved 2019-07-13.

- ^ Jump up to: a b "Wind Turbine Air Compressor". researchgate.net. Retrieved 2015-07-13.

- ^ Jump up to: a b c "Open Accumulator Isothermal Compressed Air Energy Storage (OA-ICAES) System". researchgate.net. Retrieved 2018-07-13.

- ^ "Automated Pneumatic Bumper For Vehicle Safety". researchgate.net. 2012-05-01. Retrieved 2014-05-01.

- ^ https://www.ge.com/news/reports/20-09-2013pumping-up-the-silent-engine

- ^ Kevin Bonsor (2005-10-25). "How Air-Powered Cars Will Work". HowStuffWorks. Retrieved 2006-05-25.

- ^ Robyn Curnow (2004-01-11). "Gone with the wind". The Sunday Times (UK). London. Retrieved 2006-05-25.

- ^ Learn everything about the compressed air cars! Archived 2013-05-20 at the Wayback Machine.

- ^ "MDI's active chamber". Thefuture.net.nz. Archived from the original on 2011-05-07. Retrieved 2010-12-12.

- ^ "Tata Air Car to drive in by 2011". Popular Mechanics. Archived from the original on 2010-02-10.

- ^ "An engine which uses air as fuel: Tata Motors and technology inventor, MDI of France, sign agreement" (Press release). Tata Motors. February 5, 2007. Archived from the original on March 14, 2012. Retrieved June 14, 2012.

- ^ "MDI's air engine technology tested on Tata Motors vehicles" (Press release). Tata Motors. May 7, 2012. Archived from the original on May 9, 2013. Retrieved June 14, 2012.

- ^ Tata Motors enters second phase of air-car development Gizmag.com, 2012-05-07[unreliable source?]

- ^ "Tata Motors' air-powered car project still on, to be launch ready in 3 years". Auto Car Professional. Retrieved 24 August 2017.

- ^ "Tata Nano could spawn electric, hybrid & air-powered variants – Report". Indian Autos Blog. Jan 25, 2017. Retrieved 23 August 2017.

- ^ "Nano was to run on air, battery but Ratan Tata couldn't implement plans". Hindustan Times. Oct 28, 2016. Retrieved 23 August 2017.

- ^ Matt Campbell (November 3, 2011). "The motorbike that runs on air". Sydney Morning Herald. Archived from the original on November 5, 2011. Retrieved 2011-11-07.

- ^ "Compressed-Air Hybrid Car Developed". Gas2.org. 2013-02-18. Retrieved 2013-09-08.

- ^ Marc Carter. "Peugeot Announces Plans to Release a Hybrid Car That Runs on Compressed Air by 2016". Retrieved 30 May 2015.

- ^ Duff, Mike (January 26, 2015). "Deflated: Peugeot Citroen Shelves Its Air Hybrid Technology". Car and Driver. Retrieved 2018-10-29.

- ^ Fansilber, Maxime Amiot Denis (November 1, 2015). "PSA : la révolution de l'Hybrid Air n'aura pas lieu". Les Echos (in French). Retrieved 2018-10-29.

- ^ "Association de Promotion des Usages de la Quasiturbine". APUQ. Archived from the original on 2016-03-04. Retrieved 2012-01-26.[unreliable source?]

External links[]

| Wikimedia Commons has media related to Compressed-air-powered automobiles. |

- Fairley, Peter (November 2009). "Deflating the Air Car". IEEE Spectrum. Archived from the original on 2018-05-05. Retrieved 2009-11-23.

- "Scuderi Group to Present Preliminary Results on Air-Hybrid Study and Update on Scuderi Engine Prototype Testing at Washington Auto Show". Green Car Congress. BioAge Group. January 16, 2010.

- Automotive technologies

- Compressed air power