Train wheel

A train wheel or rail wheel is a type of wheel specially designed for use on railway tracks. The wheel acts as a rolling component, typically pushed onto an axle and mounted directly on a railway carriage or locomotive, or indirectly on a bogie (in the UK), also called a truck (in North America). The powered wheels under the locomotive are called driving wheels. Wheels are initially cast or forged and then heat-treated to have a specific hardness.[1] New wheels are machined using a lathe to a standardized shape, called a profile, before being installed onto an axle. All wheel profiles are regularly checked to ensure proper interaction between the wheel and the rail. Incorrectly profiled wheels and worn wheels can increase rolling resistance, reduce energy efficiency and may even cause a derailment.[2]

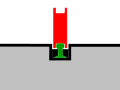

Wheel geometry and flange[]

Tram wheel flange (right)

Almost all train wheels have a curved projection, a flange, on one side to keep the wheels, and hence the train, running on the rails when the limits or tests of alignment are reached: when a bend is taken at appropriate speed, when there are strong sidebreezes, and to withstand e.g. most common emergent defects in trackbed, rail and mild debris. See Hunting oscillation. The running surface of most is concave, serving as the primary means of keeping the train's motion aligned with the track while in others it is flat such that the flanges are essential to keep the train on the rail track.[3]

Wheel arrangement[]

The number of wheels per locomotive or car vary in both size and number to accommodate the needs of the railcar or locomotive. Regardless of these factors, pairs of identically sized wheels are always affixed to a straight axle as a singular unit, called a wheelset.[3]

Wheels for road-rail vehicles[]

Wheels used for road-rail vehicles are normally smaller than those found on other types of rolling stock (such as locomotives or carriages). This is because the wheel has to be stored clear of the ground when the vehicle is in road-going mode - Such wheels can be as small as 245 mm (9.65 in) in diameter. In Australia, wheels for road-rail vehicles should comply with the requirements of AS7514.4, which is the standard for infrastructure maintenance vehicle wheels.

Railway Wheel and Tire[]

Historically, a railroad wheel consisted of two main parts: the wheel itself, and the tire (or tyres in British English, Australian English and others) around the outside. The wheels of many rail vehicles, especially steam locomotives and older types of rolling stock, are fitted with these steel tires to provide a replaceable wearing element on a costly wheel. A rail tire was usually made from iron or steel, and is typically heated and pressed onto the wheel where it remains firmly as it shrinks and cools. Resilient rail wheels have a resilient material, such as rubber, between the wheel and tire.

Causes of damage[]

The most common cause of wheel damage is severe braking. This activity includes sudden braking, braking on steep gradients and braking with high weight loads. The brake shoes (or blocks) are applied directly to the wheel surface which generates immense amounts of thermal energy. Under severe braking conditions, the generated thermal energy can contribute to thermal shock or alteration of the wheel's mechanical properties. Ultimately, acute thermal loading leads to a phenomenon called spalling. Alternatively, severe braking or low adhesion may stop the rotation of the wheels while the vehicle is still moving, which may cause a flat spot on the wheel-rail interface and localized heat damage.

Modern railway wheels are manufactured reasonably thick to provide an allowance of wear material. Worn wheels or wheels with a flat spot are machined on a wheel lathe if there is sufficient thickness of material remaining.[4]

Guide wheel[]

Rubber-tyred metros with a central guide rail, such as the Dusan Metro, Lille Metro and the Sapporo Municipal Subway as well as rubber-tyred trams have guide wheels.

See also[]

- Adhesive weight

- Conical shape

References[]

- ^ "Wheel–Rail Interface Handbook". ScienceDirect. Retrieved 2020-10-29.

- ^ Lewis, Roger; Olofsson, Ulf (2009). Wheel-rail interface handbook. Boca Raton, Florida: CRC Press. ISBN 978-1-61583-153-1. OCLC 500906475.

- ^ Jump up to: a b "Book : The Contact Patch". the-contact-patch.com. Retrieved 2020-10-29.

- ^ Nielsen, J. (2009-01-01), Lewis, R.; Olofsson, U. (eds.), "8 - Out-of-round railway wheels", Wheel–Rail Interface Handbook, Woodhead Publishing, pp. 245–279, doi:10.1533/9781845696788.1.245, ISBN 978-1-84569-412-8, retrieved 2020-10-29

ISO 1005 Parts 1-9 BS 5892 Parts 1-6 AS7414.4

External links[]

- "APTA PR-CS-RP-003-98 Recommended Practice for Developing a Clearance Diagram for Passenger Equipment 5.3.2.1 Design tolerances" (PDF). APTA.com. American Public Transportation Association. 1998-03-26. Retrieved 2015-01-17.

- Train wheels

- Train wheels