Small wind turbine

Small wind turbines, also known as micro wind turbines, are used for microgeneration of electricity, as opposed to large commercial wind turbines, such as those found in wind farms. Small wind turbines often have passive yaw systems as opposed to active ones. They use a direct drive generator and use a tail fin to point into the wind, whereas larger turbines have geared powertrains that are actively pointed into the wind.

Small wind turbines typically produce between 500 W and 10 kW of power, although the smaller turbines may be as small as a 50 Watt auxiliary power generator for a boat, caravan, or miniature refrigeration unit, and the Canadian Wind Energy Association (CanWEA) defines "small wind" as high as 300 kW.[1] The IEC 61400 Standard defines small wind turbines as wind turbines with a rotor swept area smaller than 200 m2, generating at a voltage below 1000 Va.c. or 1500 Vd.c.

Design[]

Blades[]

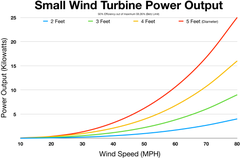

Smaller scale turbine blades are usually 1.5 to 3.5 metres (4 ft 11 in–11 ft 6 in) in diameter and produce 0.5-10 kW of electricity at their optimal wind speed.[1] The majority of small wind turbines are traditional horizontal-axis wind turbines.[2] In some situations, vertical axis wind turbines have operational advantages in maintenance and placement due to their simplicity, however VAWTs are less reliable than HAWTs and less efficient at converting wind to electricity.[3] The ratio between the speed of the blade tips and the speed of the wind is called the tip speed ratio. This should be kept at an optimal point of efficiency. A high lift-to-drag ratio will generally increase efficiency as well.

A range of synthetic materials including carbon fiber reinforced polymers, nanocomposites,[4] and E-glass-polyester are available.[5] Although natural fibers are susceptible to quality variations, high moisture uptake and low thermal stability that make them undesirable for larger blades, small turbines can still take advantage of them.[6] Wood can be used, and the type of wood should be chosen based on availability, cost and growth time, average density, high stiffness, and breaking strain. Coatings are generally used to reduce moisture, and white enamel with primer has been found to be particularly effective.[7] Sitka spruce (used in propellers), and Douglas Fir have been used in turbine blades.[8] Nepal has used small blade turbines made of coated timber including Sal, Saur, Sisau, Uttish, Tuni, Okhar, pine, and lakuri wood.[9] Beyond wood, bamboo-based composites may also be used in both large and small wind turbines due to their low density and carbon sequestration ability—which makes bamboo materials environmentally friendly. Furthermore, relative to wood, bamboo has higher fracture toughness, higher strength, lower processing costs and fast growth rate. Ongoing materials developments include bamboo laminates using resins and hybrid bamboo carbon-fiber materials.[10] Hemp, flax, wood and bamboo are all candidate blade materials for small turbines.[11]

Placement[]

Small wind turbines require a minimum wind speed to start generating, called the cut-in speed. This speed is typically around 4 metres per second (8.9 mph),[12] although some small wind turbines can be designed to work at lower wind speeds.[13] Turbines are often mounted on a tower to raise them above any nearby obstacles. One rule of thumb is that turbines should be at least 9 m (30 ft) higher than anything within 150 m (490 ft).[14] Better locations for wind turbines are far away from large upwind obstacles. Measurements made in a boundary layer wind tunnel have indicated that significant detrimental effects associated with nearby obstacles can extend up to 80 times the obstacle's height downwind.[15] However, this is an extreme case. Another approach to siting a small turbine is to use a shelter model to predict how nearby obstacles will affect local wind conditions. Models of this type are general and can be applied to any site. They are often developed based on actual wind measurements, and can estimate flow properties such as mean wind speed and turbulence levels at a potential turbine location, taking into account the size, shape, and distance to any nearby obstacles.[16]

A small wind turbine can be installed on a roof. Installation issues then include the strength of the roof, vibration, and the turbulence caused by the roof ledge. Small-scale rooftop turbines suffer from turbulence and rarely generate significant amounts of power, especially in towns and cities.[17]

Wiring[]

The generators for small wind turbines are usually three-phase alternating current generators and the trend is to use the induction type, although some models utilize single-phase generators or direct current output.[18][19]

After running the three phase AC wire through a slip ring and down to the receiving end, a three-phase rectifier is used to convert the AC to rectified DC for battery charging, especially in solar hybrid power systems. The rectifier should be mounted to a heat sink for cooling, with the option of adding a computer fan that is activated by a bimetal thermal switch for active cooling.

The DC end of the rectifier is then connected to the batteries. This connection should be as short as possible to avoid power losses, typically with a shunted digital wattmeter in between for monitoring. The batteries are then connected to a power inverter, which converts the power back to AC at a constant frequency for grid connectivity and end use.

Dynamic braking regulates the speed by dumping excess energy through a resistive load during high winds to prevent damage to the turbine. The dynamic braking resistor is often called a diversion load, or dump load. The dynamic braking is performed by a controller that is activated when the batteries go above a certain voltage, which turn on the dump load via a solenoid, or a DC/DC solid-state relay, the latter of which has the added benefit of "failing open". The controller has to be properly tuned to avoid parasitic oscillations, which can be achieved by adding a delay function, or by using a well designed stock PWM charge controller that supports a diversion function.

Cable resistant to UV radiation and temperature fluctuations, such as solar cable, should be used in cases where the wiring is exposed to the elements. The wire gauge across the whole system must be appropriate for the amount of current running through it. The resistance of the wire, which increases linearly with its length, should not create a voltage drop that is more than 2-5% of the total voltage drop.

Markets[]

Japan[]

In July 2012, a new feed-in tariff approved by Japanese Industry Minister Yukio Edano went into effect, promising to boost the country's production of wind and solar energy production. The country is aiming to increase renewable energy investment in part as a response to the Fukushima radiation crisis in March 2011.[20] The feed-in tariff applies to solar panels and small wind turbines and requires utilities to buy back electricity generated from renewable energy sources at government-established rates.

Small-scale wind power (turbines of less than 20 kW capacity) will be subsidized at least 57.75 JPY (about 0.74 USD per kwh).[21]

United Kingdom[]

Properties in rural or suburban parts of the UK can opt for a wind turbine with inverter to supplement local grid power. The UK's Microgeneration Certification Scheme (MCS) provides feed-in tariffs to owners of qualified small wind turbines.[22]

United States[]

Small wind turbines added a total of 17.3 MW of generating capacity throughout the United States in 2008, according to the American Wind Energy Association (AWEA). That growth equaled a 78% increase in the domestic market for small wind turbines, which are defined as wind turbines with capacities of 100 kW or less. AWEA's "2009 Small Wind Global Market Study", published in late 2009 May, credited the increase in part to greater manufacturing volumes, as the industry was able to attract enough private investment to finance manufacturing plant expansions. It also credited rising electricity prices and greater public awareness of wind technologies for an increase in residential sale.

In 2019, much of the US demand for small wind turbines was for power generation at remote locations, and for purposes of site assessment for large scale wind power installations.[23]

The U.S. small wind industry also benefits from the global market, as it controls about half of the global market share. U.S. manufacturers garnered $77 million of the $156 million that was spent throughout the world on small wind turbine installations. A total of 38.7 MW of small wind power capacity was installed globally in 2008.[24]

In the United States, residential wind turbines with outputs of 2–10 kW typically cost between US$12,000 and US$55,000 installed (US$6 per watt), although there are incentives and rebates available in 19 states that can reduce the purchase price for homeowners by up to 50 percent, to $3 per watt.[25] The US manufacturer Southwest Windpower estimates a turbine to pay for itself in energy savings in 5 to 12 years.[26][27]

The dominant models on the market, especially in the United States, are horizontal-axis wind turbines.[citation needed]

To enable consumers to make an informed decision when purchasing a small wind turbine, a method for consumer labeling has been developed by IEA Wind Task 27 in collaboration with IEC TC88 MT2. In 2011 IEA Wind published a Recommended Practice, which describes the tests and procedures required to apply the label.[28]

Croatia[]

Croatia is an ideal market for small wind turbines due to Mediterranean climate and numerous islands with no access to the electric grid. In winter months when there is less sun, but more wind, small wind turbines are a great addition to isolated renewable energy sites (GSM, stations, marinas etc.). That way solar and wind power provide consistent energy throughout the year.

Germany[]

In Germany the feed-in tariff for small wind turbines has always been the same as for large turbines. This is the main reason the small wind turbine sector in Germany developed slowly. In contrast, small photovoltaic systems in Germany benefited from a high feed-in tariff, at times above 50 Euro-Cent per kilowatt hour.

In August 2014 the German renewable energy law was adjusted, also affecting the feed-in tariffs for wind turbines. For the operation of a small wind turbine with a capacity below 50 kilowatt the tariff amounts to 8.5 Euro-Cent for a period of 20 years.

Due to the low feed-in tariff and high electricity prices in Germany, the economic operation of a small wind turbine depends on a large self-consumption rate of the electricity produced by the small wind turbine. Private households pay on average 28 cent per kilowatt hour for electricity (19% VAT included).

As part of the German renewable energy law 2014 a fee on self-consumed electricity was introduced in August 2014. The regulation does not apply to small power plants with a capacity below 10 kilowatt. With an amount of 1.87 Euro-Cents the fee is low.[30]

Manufacturing[]

DIY construction[]

Some hobbyists have built wind turbines from kits, sourced components, or from scratch. DIY wind turbines are usually smaller (rooftop) turbines of approximately 1 kW or less.[31][32][33][34] These small wind turbines are usually tilt-up or fixed / guyed towers.[35][36]

Do it yourself or DIY-wind turbine construction has been made popular by magazines such as and Home Power.[37]

Organizations as Practical Action have designed DIY wind turbines that can be easily built by communities in developing nations and are supplying concrete documents on how to do so.[38][39]

Local manufacturing[]

Designs of DIY small wind turbines date back to the early 1970s, and were further developed by the back-to-the-land movement of the late 1970s in the United States and Europe.[40]

Locally manufactured small wind turbines, being small-scale, low-cost, socially-embedded, adoptive to local contexts and based on the open sharing of knowledge, have been framed under or associated with the perspectives of appropriate or intermediate technology, convivial technology, degrowth, open design and open manufacturing.

See also[]

- WWEA (World Wind Energy Association)

- Open source hardware

- Wind turbine design

- Grid-tied electrical system

- Ram air turbine

References[]

- ^ Jump up to: a b Small Wind Turbine Purchasing Guide (PDF) (Report). Canadian Wind Energy Association. pp. 3–4. Archived from the original (PDF) on 2 March 2013. Retrieved 1 March 2016.

- ^ Gipe, Paul. Wind energy basics: a guide to home- and community-scale wind energy systems. Chelsea Green Publishing, 2009. Accessed: 18 December 2010. ISBN 1-60358-030-1 ISBN 978-1-60358-030-4

- ^ LuvSide. "5 Disadvantages of Vertical Axis Wind Turbine (VAWT) | The Windy Blog". www.luvside.de/en/. Retrieved 2021-03-11.

- ^ Thirumalai, Durai Prabhakaran Raghavalu; Kale, Sandip A.; Prabakar, K., eds. (2015). Renewable Energy and Sustainable Development. ISBN 9781634634649.

- ^ Sessarego, Matias; Wood, David (2015). "Multi-dimensional optimization of small wind turbine blades". Renewables: Wind, Water, and Solar. 2 (1). doi:10.1186/s40807-015-0009-x. ISSN 2198-994X.

- ^ Kalagi, Ganesh; Patil, Rajashekar; Nayak, Narayan (2016). "Natural Fiber Reinforced Polymer Composite Materials for Wind Turbine Blade Applications" (PDF). International Journal of Scientific Development and Research. 1: 28–37.

- ^ Sinha, Rakesh; Acharya, Parash; Freere, Peter; Sharma, Ranjan; Ghimire, Pramod; Mishnaevsky, Leon (2010). "Selection of Nepalese Timber for Small Wind Turbine Blade Construction". Wind Engineering. 34 (3): 263–276. doi:10.1260/0309-524X.34.3.263. ISSN 0309-524X.

- ^ Wood, David (2011), "Blade Design, Manufacture, and Testing", Small Wind Turbines, Green Energy and Technology, Springer London, pp. 119–143, doi:10.1007/978-1-84996-175-2_7, ISBN 9781849961745

- ^ Mishnaevsky, Leon; Freere, Peter; Sinha, Rakesh; Acharya, Parash; Shrestha, Rakesh; Manandhar, Pushkar (2011). "Small wind turbines with timber blades for developing countries: Materials choice, development, installation and experiences". Renewable Energy. 36 (8): 2128–2138. doi:10.1016/j.renene.2011.01.034.

- ^ Holmes, John W.; Brøndsted, Povl; Sørensen, Bent F.; Jiang, Zehui; Sun, Zhengjun; Chen, Xuhe (2009). "Development of a Bamboo-Based Composite as a Sustainable Green Material for Wind Turbine Blades". Wind Engineering. 33 (2): 197–210. doi:10.1260/030952409789141053. ISSN 0309-524X.

- ^ Bron̜dsted, Povl; Nijssen, Rogier P. L., eds. (2013). Advances in wind turbine blade design and materials. Oxford: Woodhead Publishing. ISBN 9780857097286. OCLC 864361386.

- ^ Small Wind Turbine Purchasing Guide (PDF) (Report). Canadian Wind Energy Association. p. 6. Archived from the original (PDF) on 2 March 2013. Retrieved 1 March 2016.

- ^ Luleva, Mila (28 October 2013). "Small-Scale "Dragonfly" Wind Turbine Works at Low Wind Speeds". Green Optimistic. Retrieved 18 September 2015.

- ^ Hugh Piggott (6 January 2007). "Windspeed Measurement In The City". Scoraigwind.com. Retrieved 4 December 2011.

- ^ "Wind tunnel measurements near an obstacle". Ntrs.nasa.gov. 15 October 2011. Retrieved 4 December 2011.

- ^ "Development of a Neural Network based Obstacle Wake Model" (PDF). Retrieved 4 December 2011.[dead link]

- ^ Leake, Jonathan (2006-04-16). "Home wind turbines dealt killer blow". The Sunday Times. UK. Retrieved 2009-07-13.

- ^ Forsyth, Trudy (20 May 2009). "Small Wind Technology" (PDF). National Renewable Energy Laboratory. Archived from the original (PDF) on 17 March 2013. Retrieved 20 September 2013.

- ^ "Endurance E-3120-50 kW Wind Turbine from Endurance Wind Power". AZoNetwork. 13 May 2010. Retrieved 20 September 2013.

- ^ "Japan approves renewable subsidies in shift from nuclear power". Reuters. 2012-06-18. Retrieved 18 June 2012.

- ^ "Japan Approves Feed-in Tariffs". Reuters. 2012-06-22. Retrieved 22 June 2012.

- ^ "Feed-In Tariffs Scheme (FITs)". MCS. Retrieved 29 December 2012.

- ^ Casey, Tina (2019-09-19). "What's Up With The Micro Wind Turbines? They're Up!". CleanTechnica. Retrieved 2019-09-21.

- ^ "EERE News: AWEA: U.S. Market for Small Wind Turbines Grew 78% in 2008". Apps1.eere.energy.gov. Retrieved 4 December 2011.

- ^ Shevory, Kristina (13 December 2007). "Homespun Electricity, From the Wind". The New York Times. Retrieved 4 December 2011.

- ^ "Southwest Windpower". Windenergy.com. Archived from the original on 11 January 2012. Retrieved 4 December 2011.

- ^ "Wind Power for Commercial Projects: Case Studies". XZERES. Retrieved 18 September 2015.

- ^ "IEA Wind Home Page". Ieawind.org. Retrieved 4 December 2011.

- ^ "Kako i zašto ostvarujemo najbolje rezultate" (in Hungarian). Veneko. Retrieved 18 September 2015.

- ^ "German Small Wind Turbine Portal". klein-windkraftanlagen.com. Retrieved 4 February 2015.

- ^ "British Wind and Energy Agency's DIY wind turbines page". Bwea.com. Archived from the original on 4 December 2011. Retrieved 4 December 2011.

- ^ "Common FAQs of wind turbine construction and info for proper building". Wind-turbine-24v.com. Retrieved 4 December 2011.

- ^ "Overview of wind turbine construction and info for proper building". Otherpower.com. Retrieved 4 December 2011.

- ^ Diy wind turbine 1kw. Youtube. 7 May 2015. Retrieved 18 September 2015.

- ^ "Smaller wind turbines usually of tilt-up or fixed design". Archived from the original on 1 October 2011. Retrieved 4 December 2011.

- ^ "Modified Chispito Wind Turbine". Greenterrafirma.com. Retrieved 4 December 2011.

- ^ "OtherPower and Home Power as popular diy microgeneration magazines" (PDF). Retrieved 4 December 2011.

- ^ "Practical action producing info to construct DIY wind turbines for the developing world". Practicalaction.org. Retrieved 4 December 2011.

- ^ "Basics on diy small scale windturbines and domestic power consumption" (PDF). Retrieved 4 December 2011.

- ^ Latoufis, Kostas C.; Pazios, Thomas V.; Hatziargyriou, Nikos D. (March 2015). "Locally Manufactured Small Wind Turbines: Empowering communities for sustainable rural electrification". IEEE Electrification Magazine. 3 (1): 68–78. doi:10.1109/MELE.2014.2380073. ISSN 2325-5897.

Further reading[]

- Dan Fink; Dan Bartmann (2008). Homebrew Wind Power. Buckville Publications LLC. ISBN 978-0-9819201-0-8.CS1 maint: multiple names: authors list (link)

External links[]

| Wikimedia Commons has media related to Micro-generation wind turbines. |

- Small wind turbines solving big problems

- information about small wind market by WWEA

- Bladeless wind turbine

- A Dutch government test of 10 wind turbines[permanent dead link] (English summary: [1], [2])

- Make small wind turbine at home Complete video and image Guide by Newphysicist

- Challenges of Introducing Reliable Small Wind Turbines

- Fact sheet from the American Wind Energy Association

- Otherpower, a group of alternative energy enthusiasts

- An example of DIY small wind turbine

- Small wind turbines

- Distributed generation