Hydrogen production

Hydrogen production is the family of industrial methods for generating hydrogen gas. As of 2020, the majority of hydrogen (∼95%) is produced from fossil fuels by steam reforming of natural gas, partial oxidation of methane, and coal gasification.[1][2] Other methods of hydrogen production include biomass gasification, no CO2 emissions methane pyrolysis, and electrolysis of water. The latter processes, methane pyrolysis as well as water electrolysis can be done directly with any source of electricity, such as solar power.

The production of hydrogen plays a key role in any industrialized society, since hydrogen is required for many essential chemical processes.[3] In 2020, roughly 87 million tons of hydrogen was produced[4] worldwide for various uses, such as oil refining, and in the production of ammonia (through the Haber process) and methanol (through reduction of carbon monoxide), and also as a fuel in transportation. The hydrogen generation market was expected to be valued at US$115.25 billion in 2017.[5]

Methods of hydrogen production[]

There are four main sources for the commercial production of hydrogen: natural gas, oil, coal, and electrolysis; which account for 48%, 30%, 18% and 4% of the world's hydrogen production respectively.[6] Fossil fuels are the dominant source of industrial hydrogen.[7] Carbon dioxide can be separated from natural gas with a 70–85% efficiency for hydrogen production and from other hydrocarbons to varying degrees of efficiency.[8] Specifically, bulk hydrogen is usually produced by the steam reforming of methane or natural gas.[9]

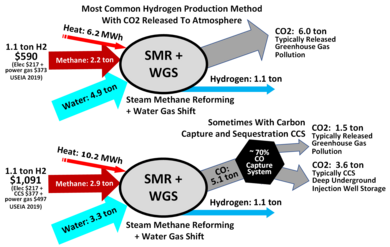

Steam reforming (SMR)[]

Steam reforming is a hydrogen production process from natural gas. This method is currently the cheapest source of industrial hydrogen. The process consists of heating the gas to between 700–1100 °C in the presence of steam and a nickel catalyst. The resulting endothermic reaction breaks up the methane molecules and forms carbon monoxide CO and hydrogen H2. The carbon monoxide gas can then be passed with steam over iron oxide or other oxides and undergo a water gas shift reaction to obtain further quantities of H2. The downside to this process is that its byproducts are major atmospheric release of CO2, CO and other greenhouse gases.[6] Depending on the quality of the feedstock (natural gas, rich gases, naphtha, etc.), one ton of hydrogen produced will also produce 9 to 12 tons of CO2, a greenhouse gas that may be captured.[10]

For this process high temperature (700–1100 °C) steam (H2O) reacts with methane (CH4) in an endothermic reaction to yield syngas.[11]

- CH4 + H2O → CO + 3 H2

In a second stage, additional hydrogen is generated through the lower-temperature, exothermic, water gas shift reaction, performed at about 360 °C:

- CO + H2O ��� CO2 + H2

Essentially, the oxygen (O) atom is stripped from the additional water (steam) to oxidize CO to CO2. This oxidation also provides energy to maintain the reaction. Additional heat required to drive the process is generally supplied by burning some portion of the methane.

Other production methods from fossil fuels[]

Methane pyrolysis[]

Pyrolysis of methane is a hydrogen production process from natural gas. Hydrogen separation occurs in one step via flow through a molten metal catalyst in a "bubble column".[12] It is a "no greenhouse gas" approach for potentially low-cost hydrogen production being measured for its capability to scale up[13] and for operation at scale.[14][15] The process is conducted at higher temperatures (1065 °C or 1950 °F).[16][17][18]

- CH

4(g) → C(s) + 2 H

2(g) ΔH° = 74 kJ/mol

The industrial quality solid carbon can then be sold as manufacturing feedstock or landfilled, it is not released into the atmosphere and no ground water pollution in landfill.

Partial oxidation[]

Hydrogen production from natural gas or other hydrocarbons is achieved by partial oxidation. A fuel-air or fuel-oxygen mixture is partially combusted resulting in a hydrogen rich syngas. Hydrogen and carbon monoxide are obtained via the water-gas shift reaction.[6] Carbon dioxide can be co-fed to lower the hydrogen to carbon monoxide ratio.

The partial oxidation reaction occurs when a substoichiometric fuel-air mixture or fuel-oxygen is partially combusted in a reformer or partial oxidation reactor. A distinction is made between thermal partial oxidation (TPOX) and catalytic partial oxidation (CPOX). The chemical reaction takes the general form:

- CnHm + n/2 O2 → n CO + m/2 H2

Idealized examples for heating oil and coal, assuming compositions C12H24 and C24H12 respectively, are as follows:

- C12H24 + 6 O2 → 12 CO + 12 H2

- C24H12 + 12 O2 → 24 CO + 6 H2

Plasma reforming[]

The Kværner-process or Kvaerner carbon black & hydrogen process (CB&H)[19] is a plasma reforming method, developed in the 1980s by a Norwegian company of the same name, for the production of hydrogen and carbon black from liquid hydrocarbons (CnHm). Of the available energy of the feed, approximately 48% is contained in the hydrogen, 40% is contained in activated carbon and 10% in superheated steam.[20] CO2 is not produced in the process.

A variation of this process is presented in 2009 using plasma arc waste disposal technology for the production of hydrogen, heat and carbon from methane and natural gas in a plasma converter[21]

From coal[]

For the production of hydrogen from coal, coal gasification is used. The process of coal gasification uses steam and oxygen to break molecular bonds in coal and form a gaseous mixture of hydrogen and carbon monoxide.[22] Carbon dioxide and other pollutants may be more easily removed from gas obtained from coal gasification versus coal combustion.[23][24] Another method for conversion is low temperature and high temperature coal carbonization.[25]

Coke oven gas made from pyrolysis (oxygen free heating) of coal has about 60% hydrogen, rest being CH4, CO,CO2, NH3, N2,and H2S. Hydrogen can be separated from other impurities by pressure swing adsorption process. Japanese steel companies have carried out production of hydrogen by this.

From petroleum coke[]

Petroleum coke can also be converted to hydrogen rich syngas via coal gasification. The produced syngas consists mainly of hydrogen, carbon monoxide and H2S from the sulfur in the coke feed. Gasification is an option for producing hydrogen from almost any carbon source.[26]

From water[]

Methods to produce hydrogen without the use of fossil fuels involve the process of water splitting, or splitting the water molecule H2O into its components oxygen and hydrogen. When the source of energy for water splitting is renewable or low-carbon, the hydrogen produced is sometimes referred to as green hydrogen. The conversion can be accomplished in several ways, but all methods are generally more expensive than fossil-fuel based production methods.

Electrolysis[]

Around 8 GW of electrolysis capacity is installed worldwide in 2020, accounting for around 4% of global hydrogen production.[27]

Electrolysis consists of using electricity to split water into hydrogen and oxygen. Electrolysis of water is 70–80% efficient (a 20–30% conversion loss)[28][29] while steam reforming of natural gas has a thermal efficiency between 70–85%.[30] The electrical efficiency of electrolysis is expected to reach 82–86%[31] before 2030, while also maintaining durability as progress in this area continues at a pace.[32]

Water electrolysis can operate between 50–80 °C, while steam methane reforming requires temperatures between 700–1100 °C.[33] The difference between the two methods is the primary energy used; either electricity (for electrolysis) or natural gas (for steam methane reforming). Due to their use of water, a readily available resource, electrolysis and similar water-splitting methods have attracted the interest of the scientific community. With the objective of reducing the cost of hydrogen production, renewable sources of energy have been targeted to allow electrolysis.[22]

There are three main types of cells, solid oxide electrolyser cells (SOECs), polymer electrolyte membrane cells (PEM) and alkaline electrolysis cells (AECs).[34] Traditionally, alkaline electrolysers are cheaper in terms of investment (they generally use nickel catalysts), but less efficient; PEM electrolysers, conversely, are more expensive (they generally use expensive platinum group metal catalysts) but are more efficient and can operate at higher current densities, and can therefore be possibly cheaper if the hydrogen production is large enough.[citation needed]

SOECs operate at high temperatures, typically around 800 °C. At these high temperatures a significant amount of the energy required can be provided as thermal energy (heat), and as such is termed High temperature electrolysis. The heat energy can be provided from a number of different sources, including waste industrial heat, nuclear power stations or concentrated solar thermal plants. This has the potential to reduce the overall cost of the hydrogen produced by reducing the amount of electrical energy required for electrolysis.[35][36][37][38] PEM electrolysis cells typically operate below 100 °C.[35] These cells have the advantage of being comparatively simple and can be designed to accept widely varying voltage inputs which makes them ideal for use with renewable sources of energy such as solar PV.[39] AECs optimally operate at high concentrations electrolyte (KOH or potassium carbonate) and at high temperatures, often near 200 °C.

Industrial output and efficiency[]

Efficiency of modern hydrogen generators is measured by energy consumed per standard volume of hydrogen (MJ/m3), assuming standard temperature and pressure of the H2. The lower the energy used by a generator, the higher would be its efficiency; a 100%-efficient electrolyser would consume 39.4 kilowatt-hours per kilogram (142 MJ/kg) of hydrogen,[40] 12,749 joules per litre (12.75 MJ/m3). Practical electrolysis typically uses a rotating electrolyser, where centrifugal force helps separate gas bubbles from water.[41] Such an electrolyser at 15 bar pressure may consume 50 kilowatt-hours per kilogram (180 MJ/kg), and a further 15 kilowatt-hours (54 MJ) if the hydrogen is compressed for use in hydrogen cars.[42]

Conventional alkaline electrolysis has an efficiency of about 70%,[43] however advanced alkaline water electrolyser with efficiency of up to 82% are available.[44] Accounting for the use of the higher heat value (because inefficiency via heat can be redirected back into the system to create the steam required by the catalyst), average working efficiencies for PEM electrolysis are around 80%, or 82% using the most modern alkaline electrolysers.[45]

PEM efficiency is expected to increase to approximately 86%[46] before 2030. Theoretical efficiency for PEM electrolysers is predicted up to 94%.[47]

As of 2020, the cost of hydrogen by electrolysis is around $3-8/kg.[48] Considering the industrial production of hydrogen, and using current best processes for water electrolysis (PEM or alkaline electrolysis) which have an effective electrical efficiency of 70–82%,[49][50][51] producing 1 kg of hydrogen (which has a specific energy of 143 MJ/kg or about 40 kWh/kg) requires 50–55 kWh of electricity. At an electricity cost of $0.06/kWh, as set out in the Department of Energy hydrogen production targets for 2015,[52] the hydrogen cost is $3/kg. The US DOE target price for hydrogen in 2020 is $2.30/kg, requiring an electricity cost of $0.037/kWh, which is achievable given recent PPA tenders for wind and solar in many regions.[53] The report by IRENA.ORG is an extensive factual report of present day industrial hydrogen production consuming about 53 to 70 kwh per kg could go down to about 45 kwh/kg H2.[54] The thermodynamic energy required for hydrogen by electrolysis translates to 33 kwh/kg, which is higher than steam reforming with carbon capture and higher than methane pyrolysis. One of the advantages of electrolysis over hydrogen from steam methane reforming (SMR) is that the hydrogen can be produced on-site, meaning that the costly process of delivery via truck or pipeline is avoided.

Steam methane reforming is between $1[48]–3/kg on average.[citation needed] This makes production of hydrogen via electrolysis cost competitive in many regions already, as outlined by Nel Hydrogen[55] and others, including an article by the IEA[56] examining the conditions which could lead to a competitive advantage for electrolysis.

Chemically assisted electrolysis[]

In addition to reduce the voltage required for electrolysis via the increasing of the temperature of the electrolysis cell it is also possible to electrochemically consume the oxygen produced in an electrolyser by introducing a fuel (such as carbon/coal,[57] methanol,[58][59] ethanol,[60] formic acid,[61] glycerol,[61] etc.) into the oxygen side of the reactor. This reduces the required electrical energy and has the potential to reduce the cost of hydrogen to less than 40~60% with the remaining energy provided in this manner.[62] In addition, carbon/hydrocarbon assisted water electrolysis (CAWE) has the potential to offer a less energy intensive, cleaner method of using chemical energy in various sources of carbon, such as low-rank and high sulfur coals, biomass, alcohols and methane (Natural Gas), where pure CO2 produced can be easily sequestered without the need for separation.[63][64]

Radiolysis[]

Nuclear radiation can break water bonds through radiolysis.[65][66] In the Mponeng gold mine, South Africa, researchers found bacteria in a naturally occurring high radiation zone. The bacterial community which was dominated by a new phylotype of Desulfotomaculum, was feeding on primarily radiolytically produced hydrogen.[67]

Thermolysis[]

Water spontaneously dissociates at around 2500 °C, but this thermolysis occurs at temperatures too high for usual process piping and equipment resulting in a rather low commercialization potential. [68]

Thermochemical cycle[]

Thermochemical cycles combine solely heat sources (thermo) with chemical reactions to split water into its hydrogen and oxygen components.[69] The term cycle is used because aside from water, hydrogen and oxygen, the chemical compounds used in these processes are continuously recycled. If electricity is partially used as an input, the resulting thermochemical cycle is defined as a hybrid one.

The sulfur-iodine cycle (S-I cycle) is a thermochemical cycle processes which generates hydrogen from water with an efficiency of approximately 50%. The sulfur and iodine used in the process are recovered and reused, and not consumed by the process. The cycle can be performed with any source of very high temperatures, approximately 950 °C, such as by Concentrating solar power systems (CSP) and is regarded as being well suited to the production of hydrogen by high-temperature nuclear reactors,[70] and as such, is being studied in the High-temperature engineering test reactor in Japan.[71][72][73][74] There are other hybrid cycles that use both high temperatures and some electricity, such as the Copper–chlorine cycle, it is classified as a hybrid thermochemical cycle because it uses an electrochemical reaction in one of the reaction steps, it operates at 530 °C and has an efficiency of 43 percent.[75]

Ferrosilicon method[]

Ferrosilicon is used by the military to quickly produce hydrogen for balloons. The chemical reaction uses sodium hydroxide, ferrosilicon, and water. The generator is small enough to fit a truck and requires only a small amount of electric power, the materials are stable and not combustible, and they do not generate hydrogen until mixed.[76] The method has been in use since World War I. A heavy steel pressure vessel is filled with sodium hydroxide and ferrosilicon, closed, and a controlled amount of water is added; the dissolving of the hydroxide heats the mixture to about 93 °C and starts the reaction; sodium silicate, hydrogen and steam are produced.[77]

Photobiological water splitting[]

Biological hydrogen can be produced in an algae bioreactor.[78] In the late 1990s it was discovered that if the algae are deprived of sulfur it will switch from the production of oxygen, i.e. normal photosynthesis, to the production of hydrogen. It seems that the production is now economically feasible by surpassing the 7–10 percent energy efficiency (the conversion of sunlight into hydrogen) barrier.[79] with a hydrogen production rate of 10–12 ml per liter culture per hour.[80]

Photocatalytic water splitting[]

The conversion of solar energy to hydrogen by means of water splitting process is one of the most interesting ways to achieve clean and renewable energy systems. However, if this process is assisted by photocatalysts suspended directly in water instead of using photovoltaic and an electrolytic system the reaction is in just one step, it can be made more efficient.[81][82]

Biohydrogen routes[]

Biomass and waste streams can in principle be converted into biohydrogen with biomass gasification, steam reforming, or biological conversion like biocatalysed electrolysis[62] or fermentative hydrogen production.[7]

Among hydrogen production methods such as steam methane reforming, thermal cracking, coal and biomass gasification and pyrolysis, electrolysis, and photolysis, biological ones are more eco-friendly and less energy intensive. In addition, a wide variety of waste and low-value materials such as agricultural biomass as renewable sources can be utilized to produce hydrogen via biochemical pathways. Nevertheless, at present hydrogen is produced mainly from fossil fuels, in particular, natural gas which are non-renewable sources. Hydrogen is not only the cleanest fuel but also widely used in a number of industries, especially fertilizer, petrochemical and food ones. This makes it logical to investigate alternative sources for hydrogen production. The main biochemical technologies to produce hydrogen are dark and photo fermentation processes. In dark fermentation, carbohydrates are converted to hydrogen by fermentative microorganisms including strict anaerobe and facultative anaerobe bacteria. A theoretical maximum of 4 mol H2/mol glucose can be produced and, besides hydrogen, sugars are converted to volatile fatty acids (VFAs) and alcohols as by-products during this process. Photo fermentative bacteria are able to generate hydrogen from VFAs. Hence, metabolites formed in dark fermentation can be used as feedstock in photo fermentation to enhance the overall yield of hydrogen.[83]

Fermentative hydrogen production[]

Biohydrogen can be produced in bioreactors. The process involves bacteria consuming hydrocarbons and producing hydrogen and CO2. The CO2 and hydrogen can be separated.

Fermentative hydrogen production is the fermentative conversion of organic substrate to biohydrogen manifested by a diverse group of bacteria using multi enzyme systems involving three steps similar to anaerobic conversion. Dark fermentation reactions do not require light energy, so they are capable of constantly producing hydrogen from organic compounds throughout the day and night. Photofermentation differs from dark fermentation because it only proceeds in the presence of light. For example, photo-fermentation with Rhodobacter sphaeroides SH2C can be employed to convert small molecular fatty acids into hydrogen.[84]

Fermentative hydrogen production can be done using direct biophotolysis by green algae, indirect biophotolysis by cyanobacteria, photo-fermentation by anaerobic photosynthetic bacteria and dark fermentation by anaerobic fermentative bacteria. For example, studies on hydrogen production using H. salinarium, an anaerobic photosynthetic bacteria, coupled to a hydrogenase donor like E. coli, are reported in literature.[85] Enterobacter aerogenes is another hydrogen producer.[86]

Enzymatic hydrogen generation[]

Diverse enzymatic pathways have been designed to generate hydrogen from sugars.[87]

Biocatalysed electrolysis[]

Besides dark fermentation, electrohydrogenesis (electrolysis using microbes) is another possibility. Using microbial fuel cells, wastewater or plants can be used to generate power. Biocatalysed electrolysis should not be confused with biological hydrogen production, as the latter only uses algae and with the latter, the algae itself generates the hydrogen instantly, where with biocatalysed electrolysis, this happens after running through the microbial fuel cell and a variety of aquatic plants[88] can be used. These include reed sweetgrass, cordgrass, rice, tomatoes, lupines and algae.[89]

Nanogalvanic aluminum alloy powder[]

An aluminum alloy powder invented by the U.S. Army Research Laboratory in 2017 was shown to be capable of producing hydrogen gas upon contact with water or any liquid containing water due to its unique nanoscale galvanic microstructure. It reportedly generates hydrogen at 100 percent of the theoretical yield without the need for any catalysts, chemicals, or externally supplied power.[90][91]

Environmental impact[]

As of 2020 most of hydrogen is produced from fossil fuels, resulting in carbon emissions.[92] This is often referred to as grey hydrogen when emissions are released to the atmosphere, and blue hydrogen when emissions are captured through carbon capture and storage (CCS).[93] Blue hydrogen has been estimated to have a greenhouse gas footprint 20% greater than burning gas or coal for heat and 60% greater when compared to burning diesel for heat.[94]

Hydrogen produced using the newer non-polluting technology methane pyrolysis[95] is often referred to as turquoise hydrogen. High quality hydrogen is produced directly from natural gas and the associated non-polluting solid carbon is not released into the atmosphere and can then be sold for industrial use or stored in landfill.

Hydrogen produced from renewable energy sources is often referred to as green hydrogen. There are two practical ways of producing hydrogen from renewable energy sources. One is to use power to gas, in which electric power is used to produce hydrogen from electrolysis, and the other is to use landfill gas to produce hydrogen in a steam reformer. Hydrogen fuel, when produced by renewable sources of energy like wind or solar power, is a renewable fuel.[96]

Estimated costs of production are $1-1.80/kg for grey hydrogen and blue hydrogen,[97] and $2.50-6.80 for green hydrogen.[97]

Use of hydrogen[]

Hydrogen is used for the conversion of heavy petroleum fractions into lighter ones via hydrocracking. It is also used in other processes including the aromatization process, hydrodesulfurization and the production of ammonia via the Haber process, the primary industrial method for the production of synthetic nitrogen fertilizer for growing 47 percent of food worldwide.[98]

Hydrogen may be used in fuel cells for local electricity generation or potentially as a transportation fuel.

Hydrogen is produced as a by-product of industrial chlorine production by electrolysis. Although requiring expensive technologies, hydrogen can be cooled, compressed and purified for use in other processes on site or sold to a customer via pipeline, cylinders or trucks. The discovery and development of less expensive methods of production of bulk hydrogen is relevant to the establishment of a hydrogen economy.[7]

See also[]

- Ammonia production

- Artificial photosynthesis

- Biohydrogen

- Hydrogen analyzer

- Hydrogen compressor

- Hydrogen economy § Color codes

- Hydrogen embrittlement

- Hydrogen leak testing

- Hydrogen pipeline transport

- Hydrogen purifier

- Hydrogen purity

- Hydrogen safety

- Hydrogen sensor

- Hydrogen storage

- Hydrogen station

- Hydrogen tank

- Hydrogen tanker

- Hydrogen technologies

- Hydrogen valve

- Industrial gas

- Liquid hydrogen

- Next Generation Nuclear Plant (partly for hydrogen production)

- Hy4Heat

- Lane hydrogen producer

- Linde–Frank–Caro process

- Underground hydrogen storage

References[]

- ^ Liu, Ke; Song, Chunshan; Subramani, Velu, eds. (2009). Hydrogen and Syngas Production and Purification Technologies. doi:10.1002/9780470561256. ISBN 9780470561256.

- ^ "Life cycle emissions of hydrogen". 4thgeneration.energy. Retrieved 2020-05-27.

- ^ Energy, U. S. D. o. The Impact of Increased Use of Hydrogen on Petroleum Consumption and Carbon Dioxide Emissions. 84 (Energy Information Administration, Washington, DC, 2008)

- ^ Collins, Leigh (2021-05-18). "A net-zero world 'would require 306 million tonnes of green hydrogen per year by 2050': IEA | Recharge". Recharge | Latest renewable energy news. Archived from the original on 2021-05-21.

- ^ http://ieahydrogen.org/pdfs/Global-Outlook-and-Trends-for-Hydrogen_Dec2017_WEB.aspx

- ^ Jump up to: a b c Press, Roman J.; Santhanam, K. S. V.; Miri, Massoud J.; Bailey, Alla V.; Takacs, Gerald A. (2008). Introduction to hydrogen Technology. John Wiley & Sons. p. 249. ISBN 978-0-471-77985-8.

- ^ Jump up to: a b c Häussinger, Peter; Lohmüller, Reiner; Watson, Allan M. (2011). "Hydrogen, 1. Properties and Occurrence". Ullmann's Encyclopedia of Industrial Chemistry. doi:10.1002/14356007.a13_297.pub2. ISBN 978-3-527-30673-2.

- ^ https://cleantechnica.com/2014/06/04/hydrogen-fuel-cell-vehicles-about-not-clean/[full citation needed]

- ^ Fossil fuel processor

- ^ Collodi, Guido (2010-03-11). "Hydrogen Production via Steam Reforming with CO2 Capture" (PDF). CISAP4 4th International Conference on Safety and Environment in the Process Industry. Retrieved 2015-11-28.

- ^ "HFCIT Hydrogen Production: Natural Gas Reforming". U.S. Department of Energy. 2008-12-15.

- ^ Upham, D. Chester. "Catalytic molten metals for the direct conversion of methane to hydrogen and separable carbon in a single reaction step commercial process (at potentially low-cost). This would provide no-pollution hydrogen from natural gas, essentially forever". ScienceMag.org. American Association for Advancement of Science. Retrieved 31 October 2020.

- ^ Fernandez, Sonia. "Researchers at University of California - Santa Barbara chemical engineering team develop potentially low-cost, low-emissions, scalable technology that can convert methane to hydrogen without forming CO2". Phys-Org. American Institute of Physics. Retrieved 19 October 2020.

- ^ BASF. "BASF researchers working on fundamentally new, low-carbon hydrogen production processes, Methane Pyrolysis". United States Sustainability. BASF. Retrieved 19 October 2020.

- ^ Schneider, Stefan (2020). "State of the Art of Hydrogen Production via Pyrolysis of Natural Gas". ChemBioEng Reviews. Wiley Online Library. 7 (5): 150–158. doi:10.1002/cben.202000014.

- ^ Clarke, Palmer. "Dry reforming of methane catalyzed by molten metal alloys". nature.com. nature catalysis. Retrieved 31 October 2020.

- ^ Cartwright, Jon. "The reaction that would give us clean fossil fuels forever". NewScientist. New Scientist Ltd. Retrieved 30 October 2020.

- ^ Karlsruhe Institute of Technology. "Hydrogen from methane without CO2 emissions". Phys.Org. Phys.Org. Retrieved 30 October 2020.

- ^ Bellona-HydrogenReport

- ^ https://www.hfpeurope.org/infotools/energyinfos__e/hydrogen/main03.html[permanent dead link][full citation needed]

- ^ "Kværner-process with plasma arc waste disposal technology". Archived from the original on 2014-03-13. Retrieved 2009-10-13.

- ^ Jump up to: a b Hordeski, M. F. Alternative fuels: the future of hydrogen. 171-199 (The Fairmont Press, inc., 2007).

- ^ "Emissions Advantages of Gasification". National Energy Technology Laboratory. U.S. Department of Energy.

- ^ "Emissions from burning coal". U.S. EIA. U.S. Energy Information Administration.

- ^ Lee, Woon-Jae; Lee, Yong-Kuk (2001). "Internal Gas Pressure Characteristics Generated during Coal Carbonization in a Coke Oven". Energy & Fuels. 15 (3): 618–23. doi:10.1021/ef990178a.

- ^ Gemayel, Jimmy El; MacChi, Arturo; Hughes, Robin; Anthony, Edward John (2014). "Simulation of the integration of a bitumen upgrading facility and an IGCC process with carbon capture". Fuel. 117: 1288–97. doi:10.1016/j.fuel.2013.06.045.

- ^ Petrova, Magdalena (2020-12-04). "Green hydrogen is gaining traction, but still has massive hurdles to overcome". CNBC. Retrieved 2021-06-20.

- ^ "ITM - Hydrogen Refuelling Infrastructure - February 2017" (PDF). level-network.com. Retrieved 17 April 2018.

- ^ "Cost reduction and performance increase of PEM electrolysers" (PDF). fch.europa.eu. Fuel Cells and Hydrogen Joint Undertaking. Retrieved 17 April 2018.

- ^ "Hydrogen Production Technologies: Current State and Future Developments". hindawi.com. Retrieved 17 April 2018.

- ^ "Cost reduction and performance increase of PEM electrolysers" (PDF). fch.europa.eu. Fuel Cell and Hydrogen Joint Undertaking. Retrieved 17 April 2018.

- ^ "Report and Financial Statements 30 April 2016" (PDF). itm-power.com. Retrieved 17 April 2018.

- ^ "Hydrogen Production: Natural Gas Reforming". energy.gov. US Department of Energy. Retrieved 17 April 2018.

- ^ Badwal, Sukhvinder P.S.; Giddey, Sarbjit; Munnings, Christopher (2013). "Hydrogen production via solid electrolytic routes". Wiley Interdisciplinary Reviews: Energy and Environment. 2 (5): 473–487. doi:10.1002/wene.50.

- ^ Jump up to: a b Ogden, J.M. (1999). "Prospects for building a hydrogen energy infrastructure". Annual Review of Energy and the Environment. 24: 227–279. doi:10.1146/annurev.energy.24.1.227.

- ^ Hauch, Anne; Ebbesen, Sune Dalgaard; Jensen, Søren Højgaard; Mogensen, Mogens (2008). "Highly efficient high temperature electrolysis". Journal of Materials Chemistry. 18 (20): 2331–40. doi:10.1039/b718822f.

- ^ In the laboratory, water electrolysis can be done with a simple apparatus like a Hofmann voltameter:"Electrolysis of water and the concept of charge". Archived from the original on 2010-06-13.

- ^ "Nuclear power plants can produce hydrogen to fuel the 'hydrogen economy'" (Press release). American Chemical Society. March 25, 2012. Retrieved March 9, 2013.

- ^ Clarke, R.E.; Giddey, S.; Ciacchi, F.T.; Badwal, S.P.S.; Paul, B.; Andrews, J. (2009). "Direct coupling of an electrolyser to a solar PV system for generating hydrogen". International Journal of Hydrogen Energy. 34 (6): 2531–42. doi:10.1016/j.ijhydene.2009.01.053.

- ^ Luca Bertuccioli; et al. (7 February 2014). "Development of water electrolysis in the European Union" (PDF). Client Fuel Cells and Hydrogen Joint Undertaking.

- ^ L. Lao, C. Ramshaw and H. Yeung (2011). "Process intensification: water electrolysis in a centrifugal acceleration field". Journal of Applied Electrochemistry. 41 (6): 645–656. doi:10.1007/s10800-011-0275-2. hdl:1826/6464. S2CID 53760672. Retrieved June 12, 2011.CS1 maint: uses authors parameter (link)

- ^ Stensvold, Tore (26 January 2016). «Coca-Cola-oppskrift» kan gjøre hydrogen til nytt norsk industrieventyr. Teknisk Ukeblad, .

- ^ Stolten, Detlef (Jan 4, 2016). Hydrogen Science and Engineering: Materials, Processes, Systems and Technology. John Wiley & Sons. p. 898. ISBN 9783527674299. Retrieved 22 April 2018.

- ^ thyssenkrupp. "Hydrogen from water electrolysis - solutions for sustainability". thyssenkrupp-uhde-chlorine-engineers.com. Retrieved 28 July 2018.

- ^ "ITM - Hydrogen Refuelling Infrastructure - February 2017" (PDF). level-network.com. Retrieved 17 April 2018.

- ^ "Cost reduction and performance increase of PEM electrolysers" (PDF). fch.europa.eu. Fuel Cells and Hydrogen Joint Undertaking. Retrieved 17 April 2018.

- ^ Bjørnar Kruse; Sondre Grinna; Cato Buch (13 February 2002). "Hydrogen—Status and Possibilities" (PDF). The Bellona Foundation. p. 20. Archived from the original on 16 September 2013.CS1 maint: unfit URL (link)

- ^ Jump up to: a b Fickling, David (2 December 2020). "Hydrogen Is a Trillion Dollar Bet on the Future". Bloomberg.com. Archived from the original on 2 December 2020.

green hydrogen .. current pricing of around $3 to $8 a kilogram .. gray hydrogen, which costs as little as $1

- ^ Werner Zittel; Reinhold Wurster (1996-07-08). "Chapter 3: Production of Hydrogen. Part 4: Production from electricity by means of electrolysis". HyWeb: Knowledge - Hydrogen in the Energy Sector. Ludwig-Bölkow-Systemtechnik GmbH.

- ^ Bjørnar Kruse; Sondre Grinna; Cato Buch (2002-02-13). "Hydrogen—Status and Possibilities". The Bellona Foundation. Archived from the original (PDF) on 2011-07-02.

Efficiency factors for PEM electrolysers up to 94% are predicted, but this is only theoretical at this time.

- ^ "high-rate and high efficiency 3D water electrolysis". Grid-shift.com. Archived from the original on 2012-03-22. Retrieved 2011-12-13.

- ^ "DOE Technical Targets for Hydrogen Production from Electrolysis". energy.gov. US Department of Energy. Retrieved 22 April 2018.

- ^ Deign, Jason. "Xcel Attracts 'Unprecedented' Low Prices for Solar and Wind Paired With Storage". greentechmedia.com. Wood MacKenzie. Retrieved 22 April 2018.

- ^ https://irena.org/-/media/Files/IRENA/Agency/Publication/2020/Dec/IRENA_Green_hydrogen_cost_2020.pdf accessed June 22, 2021]

- ^ "Wide Spread Adaption of Competitive Hydrogen Solution" (PDF). nelhydrogen.com. Nel ASA. Retrieved 22 April 2018.

- ^ Philibert, Cédric. "Commentary: Producing industrial hydrogen from renewable energy". iea.org. International Energy Agency. Retrieved 22 April 2018.

- ^ Giddey, S; Kulkarni, A; Badwal, S.P.S (2015). "Low emission hydrogen generation through carbon assisted electrolysis". International Journal of Hydrogen Energy. 40 (1): 70–4. doi:10.1016/j.ijhydene.2014.11.033.

- ^ Uhm, Sunghyun; Jeon, Hongrae; Kim, Tae Jin; Lee, Jaeyoung (2012). "Clean hydrogen production from methanol–water solutions via power-saved electrolytic reforming process". Journal of Power Sources. 198: 218–22. doi:10.1016/j.jpowsour.2011.09.083.

- ^ Ju, Hyungkuk; Giddey, Sarbjit; Badwal, Sukhvinder P.S (2017). "The role of nanosized SnO2 in Pt-based electrocatalysts for hydrogen production in methanol assisted water electrolysis". Electrochimica Acta. 229: 39–47. doi:10.1016/j.electacta.2017.01.106.

- ^ Ju, Hyungkuk; Giddey, Sarbjit; Badwal, Sukhvinder P.S; Mulder, Roger J (2016). "Electro-catalytic conversion of ethanol in solid electrolyte cells for distributed hydrogen generation". Electrochimica Acta. 212: 744–57. doi:10.1016/j.electacta.2016.07.062.

- ^ Jump up to: a b Lamy, Claude; Devadas, Abirami; Simoes, Mario; Coutanceau, Christophe (2012). "Clean hydrogen generation through the electrocatalytic oxidation of formic acid in a Proton Exchange Membrane Electrolysis Cell (PEMEC)". Electrochimica Acta. 60: 112–20. doi:10.1016/j.electacta.2011.11.006.

- ^ Jump up to: a b Badwal, Sukhvinder P. S; Giddey, Sarbjit S; Munnings, Christopher; Bhatt, Anand I; Hollenkamp, Anthony F (2014). "Emerging electrochemical energy conversion and storage technologies". Frontiers in Chemistry. 2: 79. Bibcode:2014FrCh....2...79B. doi:10.3389/fchem.2014.00079. PMC 4174133. PMID 25309898.

- ^ Ju, H; Badwal, S.P.S; Giddey, S (2018). "A comprehensive review of carbon and hydrocarbon assisted water electrolysis for hydrogen production". Applied Energy. 231: 502–533. doi:10.1016/j.apenergy.2018.09.125.

- ^ Ju, Hyungkuk; Badwal, Sukhvinder; Giddey, Sarbjit (2018). "A comprehensive review of carbon and hydrocarbon assisted water electrolysis for hydrogen production". Applied Energy. 231: 502–533. doi:10.1016/j.apenergy.2018.09.125.

- ^ An Introduction to Radiation Chemistry Chapter 7

- ^ Nuclear Hydrogen Production Handbook Chapter 8

- ^ Li-Hung Lin; Pei-Ling Wang; Douglas Rumble; Johanna Lippmann-Pipke; Erik Boice; Lisa M. Pratt; Barbara Sherwood Lollar; Eoin L. Brodie; Terry C. Hazen; Gary L. Andersen; Todd Z. DeSantis; Duane P. Moser; Dave Kershaw; T. C. Onstott (2006). "Long-Term Sustainability of a High-Energy, Low-Diversity Crustal Biome". Science. 314 (5798): 479–82. Bibcode:2006Sci...314..479L. doi:10.1126/science.1127376. PMID 17053150. S2CID 22420345.

- ^ "Dream or Reality? Electrification of the Chemical Process Industries". www.aiche-cep.com. Retrieved 2021-08-22.

- ^ Producing hydrogen: The Thermochemical cycles

- ^ IEA Energy Technology Essentials - Hydrogen Production & Distribution, April 2007

- ^ "HTTR High Temperature engineering Test Reactor". Httr.jaea.go.jp. Retrieved 2014-01-23.

- ^ https://smr.inl.gov/Document.ashx?path=DOCS%2FGCR-Int%2FNHDDELDER.pdf. Progress in Nuclear Energy Nuclear heat for hydrogen production: Coupling a very high/high temperature reactor to a hydrogen production plant. 2009

- ^ Status report 101 - Gas Turbine High Temperature Reactor (GTHTR300C)

- ^ "JAEA'S VHTR FOR HYDROGEN AND ELECTRICITY COGENERATION : GTHTR300C" (PDF). Archived from the original (PDF) on 2017-08-10. Retrieved 2013-12-04.

- ^ Chukwu, C., Naterer, G. F., Rosen, M. A., "Process Simulation of Nuclear-Produced Hydrogen with a Cu-Cl Cycle", 29th Conference of the Canadian Nuclear Society, Toronto, Ontario, Canada, June 1–4, 2008. "Archived copy" (PDF). Archived from the original (PDF) on 2012-02-20. Retrieved 2013-12-04.CS1 maint: archived copy as title (link)

- ^ Report No 40: The ferrosilicon process for the generation of hydrogen

- ^ Candid science: conversations with famous chemists, István Hargittai, Magdolna Hargittai, p. 261, Imperial College Press (2000) ISBN 1-86094-228-8

- ^ Hemschemeier, Anja; Melis, Anastasios; Happe, Thomas (2009). "Analytical approaches to photobiological hydrogen production in unicellular green algae". Photosynthesis Research. 102 (2–3): 523–40. doi:10.1007/s11120-009-9415-5. PMC 2777220. PMID 19291418.

- ^ DOE 2008 Report 25 %

- ^ Jenvanitpanjakul, Peesamai (February 3–4, 2010). Renewable Energy Technology And Prospect On Biohydrogen Study In Thailand (PDF). Steering Committee Meeting and Workshop of APEC Research Network for Advanced Biohydrogen Technology. Taichung: Feng Chia University. Archived from the original (PDF) on July 4, 2013.

- ^ Navarro Yerga, Rufino M.; Álvarez Galván, M. Consuelo; Del Valle, F.; Villoria De La Mano, José A.; Fierro, José L. G. (2009). "Water Splitting on Semiconductor Catalysts under Visible-Light Irradiation". ChemSusChem. 2 (6): 471–85. doi:10.1002/cssc.200900018. PMID 19536754.

- ^ Navarro, R.M.; Del Valle, F.; Villoria De La Mano, J.A.; Álvarez-Galván, M.C.; Fierro, J.L.G. (2009). "Photocatalytic Water Splitting Under Visible Light: Concept and Catalysts Development". Photocatalytic Technologies. Advances in Chemical Engineering. 36. pp. 111–43. doi:10.1016/S0065-2377(09)00404-9. ISBN 978-0-12-374763-1.

- ^ Asadi, Nooshin; Karimi Alavijeh, Masih; Zilouei, Hamid (2017). "Development of a mathematical methodology to investigate biohydrogen production from regional and national agricultural crop residues: A case study of Iran". International Journal of Hydrogen Energy. 42 (4): 1989–2007. doi:10.1016/j.ijhydene.2016.10.021.

- ^ Tao, Y; Chen, Y; Wu, Y; He, Y; Zhou, Z (2007). "High hydrogen yield from a two-step process of dark- and photo-fermentation of sucrose". International Journal of Hydrogen Energy. 32 (2): 200–6. doi:10.1016/j.ijhydene.2006.06.034.

- ^ Rajanandam, Brijesh; Kiran, Siva (2011). "Optimization of hydrogen production by Halobacterium salinarium coupled with E coli using milk plasma as fermentative substrate". Journal of Biochemical Technology. 3 (2): 242–4.

- ^ Asadi, Nooshin; Zilouei, Hamid (March 2017). "Optimization of organosolv pretreatment of rice straw for enhanced biohydrogen production using Enterobacter aerogenes". Bioresource Technology. 227: 335–344. doi:10.1016/j.biortech.2016.12.073. PMID 28042989.

- ^ Percival Zhang, Y-H; Sun, Jibin; Zhong, Jian-Jiang (2010). "Biofuel production by in vitro synthetic enzymatic pathway biotransformation". Current Opinion in Biotechnology. 21 (5): 663–9. doi:10.1016/j.copbio.2010.05.005. PMID 20566280.

- ^ Strik, David P. B. T. B.; Hamelers (Bert), H. V. M.; Snel, Jan F. H.; Buisman, Cees J. N. (2008). "Green electricity production with living plants and bacteria in a fuel cell". International Journal of Energy Research. 32 (9): 870–6. doi:10.1002/er.1397. Lay summary – Wageningen University and Research Centre.

- ^ Timmers, Ruud (2012). Electricity generation by living plants in a plant microbial fuel cell (PhD Thesis). ISBN 978-94-6191-282-4.[page needed]

- ^ "Aluminum Based Nanogalvanic Alloys for Hydrogen Generation". U.S. Army Combat Capabilities Development Command Army Research Laboratory. Retrieved January 6, 2020.

- ^ McNally, David (July 25, 2017). "Army discovery may offer new energy source". U.S. Army. Retrieved January 6, 2020.

- ^ https://4thgeneration.energy/life-cycles-emissions-of-hydrogen/

- ^ Welle, Deutsche. "First element in periodic table: Why all the fuss about hydrogen? | DW | 12.06.2020". DW.COM.

- ^ Robert W. Howarth; Mark Z. Jacobson (12 August 2021). "How green is blue hydrogen?". Energy Science & Engineering. doi:10.1002/ESE3.956. ISSN 2050-0505. Wikidata Q108067259.

- ^ Direct CH4 methane pyrolysis can be done in a relatively simple (and potentially low-cost) commercial process in a single reaction step producing clean hydrogen from natural gas

- ^ "New Horizons for Hydrogen" (PDF). Research Review. National Renewable Energy Laboratory (2): 2–9. April 2004.

- ^ Jump up to: a b Collins, Leigh (19 March 2020). "A wake-up call on green hydrogen: the amount of wind and solar needed is immense | Recharge". Recharge | Latest renewable energy news. Archived from the original on 4 June 2021.

- ^ Ritchie, Hannah. "How many people does synthetic fertilizer feed?". Our World in Data. Global Change Data Lab. Retrieved 16 September 2021.

External links[]

| Wikimedia Commons has media related to Hydrogen production. |

- U.S. DOE 2012-Technical progress in hydrogen production

- U.S. NREL article on hydrogen production

- Komatsu, Teruyuki; Wang, Rong-Min; Zunszain, Patricia A.; Curry, Stephen; Tsuchida, Eishun (2006). "Photosensitized Reduction of Water to Hydrogen Using Human Serum Albumin Complexed with Zinc−Protoporphyrin IX". Journal of the American Chemical Society. 128 (50): 16297–301. doi:10.1021/ja0656806. PMID 17165784. Lay summary – Imperial College London (December 1, 2006). 1

Further reading[]

- Francesco Calise et al. editors (2019). Solar Hydrogen Production. Academic Press. ISBN 978-0-12-814853-2.

- Hydrogen production